SK-YJ000RFSHY-KP 100005

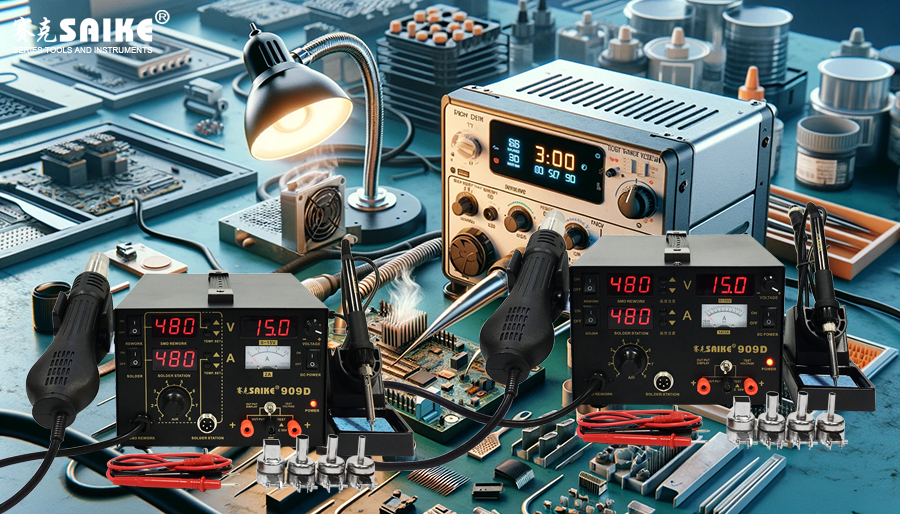

The hot air rework station is a crucial tool widely used in the maintenance and production of electronic products. It is primarily utilized for soldering and desoldering electronic components, particularly excelling in situations involving high-density packaging such as Integrated Circuits (ICs) and Surface Mount Technology (SMT) components. This article delves into the working principle of the hot air rework station and its extensive applications in practical scenarios.

I. Working Principle of the Hot Air Rework Station

The hot air rework station heats soldering points through high-temperature hot air, melting the solder and facilitating the soldering or desoldering of electronic components. Its working principle encompasses the following aspects:

1.Heating System:

– The core component is the heating system, typically consisting of an electric heater and a fan. The electric heater warms the air, and the fan blows the hot air toward the soldering points.

– The heating system offers precise temperature control, generally ranging from 100℃ to 480℃, accommodating various soldering materials and requirements.

2.Temperature Control:

– Advanced hot air rework stations are equipped with a PID temperature controller, enabling real-time monitoring and adjustment of hot air temperature for a stable and reliable heating process.

– The temperature controller often features a digital display for easy temperature setting and monitoring by operators.

3.Airflow Control:

– The fan’s speed and air volume are adjustable to control the intensity and coverage of the hot air output. Proper airflow control minimizes thermal damage to surrounding components.

– Some high-end devices come with nozzles of different sizes, adapting to components of various dimensions and shapes.

4.Static Electricity Protection:

– To prevent electrostatic damage to sensitive components, many hot air rework stations have built-in electrostatic elimination devices, ensuring a safe working environment.

II. Applications of the Hot Air Rework Station

The hot air rework station finds extensive use in electronic manufacturing and maintenance, primarily for:

1.Desoldering SMT Components:

– In electronic repairs, damaged SMT components (like resistors, capacitors, IC chips) often need to be removed. The hot air rework station rapidly heats the soldering points, melting the solder for easy component removal.

2.Soldering SMT Components:

– Besides desoldering, the station is also used for soldering new SMT components. Precise temperature and airflow control ensure reliable and sturdy soldering points.

3.Rework and Repair:

– During production, if soldering defects are detected, the hot air rework station aids in rework, allowing for re-soldering or component replacement to enhance product quality.

4.Thermal Forming of Plastics:

– The station isn’t limited to metal soldering; it’s also used for thermal forming and soldering of some plastic parts, such as the shrinkage of heat-shrinkable tubing.

5.Other Applications:

– In specific scenarios, the hot air rework station is also employed for processes like hot air drying and dehumidification.

III. Precautions When Using the Hot Air Rework Station

When operating the hot air rework station, consider the following:

1.Temperature Selection:

– Choose an appropriate temperature based on the soldering material and components. Excessively high temperatures can damage components, while too low temperatures may result in insecure soldering.

2.Airflow Adjustment:

– Adjust the airflow intensity to prevent hot air from directly blowing onto other sensitive components, causing thermal damage.

3.Static Electricity Protection:

– Implement effective electrostatic protection measures to avoid component damage due to static electricity.

4.Operational Skills:

– Maintain a steady hand during operation, keep the nozzle at a moderate distance from the soldering point, and avoid prolonged heating of any specific point to prevent circuit board damage.

5.Safety Precautions:

– Take protective measures during use to avoid hot air burns. Ensure good ventilation in the work area to prevent the inhalation of harmful gases.

IV. Conclusion

The hot air rework station serves as a vital tool in electronic product maintenance and production, facilitating efficient soldering and desoldering operations through high-temperature hot air. Its practical applications extend beyond soldering and desoldering SMT components, finding use in rework, repairs, and plastic part forming. Proper usage and maintenance of the hot air rework station not only enhance work efficiency but also ensure the quality and reliability of electronic products.