SK-YJ000RFSHY-KP 100049

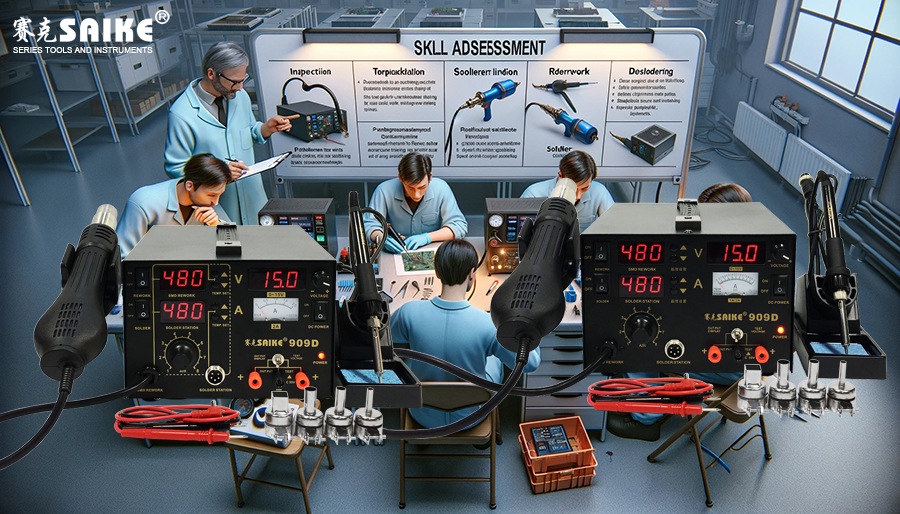

In the field of electronic manufacturing and maintenance, mastering the use of the three-in-one hot air rework station is a crucial skill. This equipment integrates a hot air gun, soldering iron, and power supply, often used for desoldering, soldering, and testing circuit components. This article will provide a detailed assessment of trainees’ operational skills in using the three-in-one hot air rework station and offer corresponding improvement suggestions.

I. Assessing Trainees’ Operational Skills

1.Preparation

– Equipment Inspection: Trainees need to ensure that all functions of the equipment are working properly and the power connection is stable.

– Safety Measures: Trainees should wear an anti-static wristband, ensure good ventilation in the work environment, and prepare protective glasses and gloves.

2.Operational Process

a.Hot Air Gun Usage:

– Temperature and Airflow Settings: Trainees should correctly set the temperature and airflow of the hot air gun according to the requirements of the components and soldering materials.

– Heating Technique: Trainees should master the correct heating angle and distance to ensure uniform heating and avoid damaging components.

b.Soldering Iron Usage:

– Temperature Setting: Properly set the temperature of the soldering iron based on soldering requirements.

– Soldering Skills: Trainees should be able to use the soldering iron tip correctly, keep it clean, and perform soldering operations accurately.

c.Power Supply Usage:

– Voltage and Current Settings: Trainees need to accurately set the voltage and current according to testing requirements.

– Testing Operations: Proficiently use probes and testing instruments for circuit testing.

3.Common Problem Handling

– Poor Soldering: Trainees should be able to identify and correct problems such as cold solder joints or false solder joints.

– Component Damage: Trainees need to understand how to avoid overheating and electrostatic damage and quickly replace damaged components.

II. Providing Improvement Suggestions

1.Enhancing Theoretical Knowledge

– Reference Materials: Read relevant books and technical documents, and participate in training courses.

– Online Resources: Utilize online tutorials and videos to learn about the latest operational techniques and industry standards.

2.Practical Operation Training

– Simulation Exercises: Perform simulation exercises on non-damaging circuit boards to familiarize themselves with various soldering and desoldering operations.

– Practical Experience: Apply learned skills in actual repair and manufacturing processes to accumulate practical experience.

3.Technical Communication and Feedback

– Technical Seminars: Participate in technical seminars organized by the company or industry organizations to share experiences and learn new technologies.

– Operational Competitions: Regularly conduct operational skill competitions to identify gaps and develop improvement plans.

4.Equipment Maintenance and Care

– Regular Inspection: Perform regular inspections and maintenance according to the equipment manual to maintain optimal equipment condition.

– Cleaning and Maintenance: Regularly clean the equipment, especially the soldering iron tip and hot air gun, to avoid oxidation and buildup affecting operational effectiveness.

III. Summary

Operational skills in using the three-in-one hot air rework station are crucial for professionals in electronic manufacturing and maintenance. Through systematic assessment and targeted improvement suggestions, trainees can continuously enhance their operational level. By strengthening theoretical knowledge, increasing practical training, actively participating in technical exchanges, and properly maintaining equipment, trainees can effectively improve their operational skills, ensuring work quality and efficiency.