SK-YJ000RFSHY-KP 100006

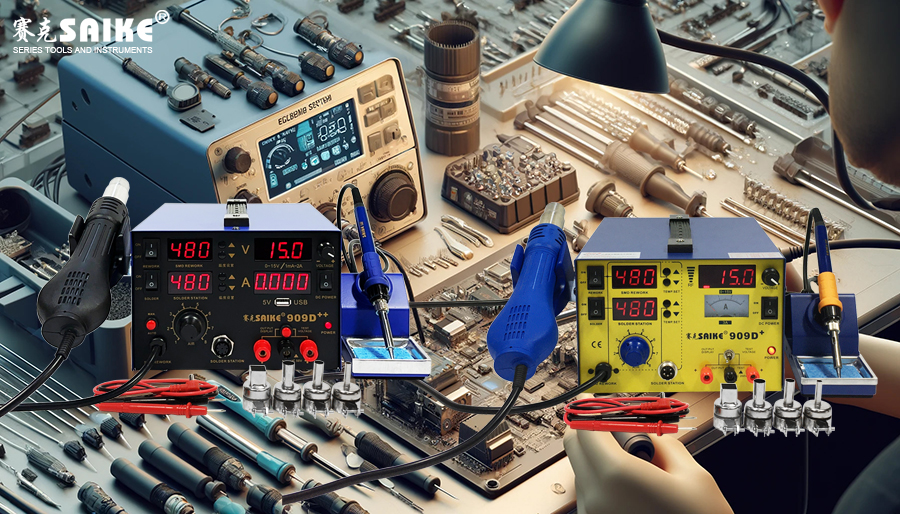

The soldering station is an indispensable tool in electronic manufacturing and repair, widely used for soldering various electronic components. This article will detail the working principle of the soldering station and its extensive applications in practical scenarios.

I. Working Principle of the Soldering Station

The soldering station operates by heating the soldering tip (also known as the soldering iron), melting the solder, and facilitating the soldering of electronic components. Its working principle primarily involves the following aspects:

1.Heating System:

– The core component of the soldering station is the heating system, typically consisting of an electric heater and a temperature controller. The electric heater warms the soldering tip to a preset temperature.

– The heating system’s temperature can be precisely controlled, usually ranging from 200°C to 480°C, to accommodate different soldering materials and requirements.

2.Temperature Control:

– Advanced soldering stations are equipped with a PID temperature controller, allowing real-time monitoring and adjustment of the soldering tip temperature to ensure a stable and reliable heating process.

– The temperature controller often features a digital display for operators to easily set and monitor the temperature.

3.Soldering Tip Design:

– The soldering tip is a crucial part of the soldering station, and its design significantly impacts soldering results. Tips come in various shapes and sizes to suit different soldering needs.

– The material used for soldering tips is often copper-plated iron, chosen for its excellent thermal conductivity and corrosion resistance.

4.Electrostatic Protection:

– To prevent electrostatic damage to sensitive components, many soldering stations have built-in electrostatic elimination devices, ensuring a safe working environment.

II. Applications of the Soldering Station

Soldering stations find extensive use in electronic manufacturing and repair, primarily for:

1.Soldering Electronic Components:

– Soldering stations are widely used for soldering various electronic components, including through-hole and surface mount devices (SMD). They provide stable heat, allowing solder to melt and solidify quickly for reliable soldering connections.

2.Desoldering Electronic Components:

– Besides soldering, soldering stations are also used to desolder damaged or replaceable components. By heating the solder joints, the solder can be re-melted, facilitating easy removal of the components.

3.Circuit Board Repair:

– In electronic repair processes, soldering stations are employed to fix issues like broken traces or defective solder joints on circuit boards. Delicate soldering operations can restore the circuit’s normal functionality.

4.Production Assembly:

– In the production assembly of electronic products, soldering stations are used for batch soldering of various components, especially in small-scale production and manual assembly processes where they are essential tools.

5.Experimental Research and Development:

– In electronic experiments and research, soldering stations aid in creating and modifying circuit prototypes. Researchers can quickly build and adjust experimental circuits by soldering various components.

III. Precautions for Using a Soldering Station

When using a soldering station, it’s essential to consider the following:

1.Temperature Selection:

– Choose an appropriate temperature based on the solder material and components. Excessively high temperatures can damage components, while too low temperatures may result in insecure soldering.

2.Soldering Tip Cleaning:

– Regularly clean the soldering tip to prevent oxidation and contaminant buildup, ensuring good thermal conductivity and soldering effectiveness. Typically, a soldering tip cleaning sponge or ball is used for cleaning.

3.Electrostatic Protection:

– Implement effective electrostatic protection measures to prevent component damage due to static electricity. Wear an anti-static wristband during soldering and ensure the workbench is grounded.

4.Operational Skills:

– Maintain a steady hand during operation, and keep the contact time between the soldering tip and the solder joint moderate to avoid prolonged heating, which can damage the circuit board and components.

5.Safety Precautions:

– Take precautions during use to prevent burns from the high-temperature soldering tip. Maintain good ventilation in the work area to avoid inhaling harmful gases.

IV. Conclusion

As a crucial tool in electronic product manufacturing and repair, the soldering station efficiently solders and desolders electronic components by heating the soldering tip. In practical applications, it plays a vital role in soldering and desoldering various components and finds extensive use in circuit board repair, production assembly, and experimental research. Proper use and maintenance of the soldering station can enhance work efficiency and ensure the quality and reliability of electronic products.