SK-YJ000HWXCHT-KP 100019

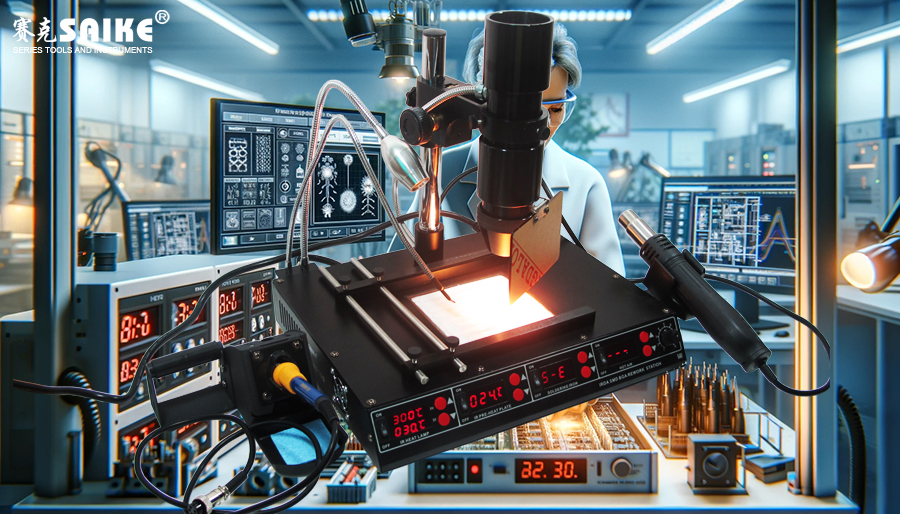

The infrared desoldering station system is a precision tool commonly used in electronic repair and manufacturing. To ensure that the equipment always maintains an efficient and precise working state, it is crucial to regularly update and upgrade the system. This article will delve into the strategies for updating and upgrading the infrared desoldering station system, focusing on hardware and software improvements to enhance overall operational efficiency, guarantee soldering quality, and extend the equipment’s lifespan.

I. Hardware Upgrades

1.Infrared Emitter Upgrade:

– Replacement with High-Efficiency Lamps: Adopt the latest generation of infrared lamps with higher power density and emission efficiency.

– Improved Reflection System: Utilize high-reflectance reflectors or lenses to ensure uniform infrared radiation coverage of the target area, reducing heat loss.

2.Temperature Sensor Improvement:

– High-Precision Sensors: Replace with more accurate infrared or thermocouple sensors for real-time, precise temperature feedback.

– Multi-Zone Sensors: Add multiple sensors to enable independent monitoring and control of different areas.

3.Control Panel Upgrade:

– Touchscreen Interface: Upgrade to a touchscreen control panel, providing an intuitive and convenient operation experience with support for multiple temperature curve programming and data logging.

– Programmable Logic Controller (PLC): Update or install a PLC to enhance the equipment’s automation capabilities.

4.Electrical and Ventilation Systems:

– Overload Protection: Upgrade overload and overheat protection devices in the electrical system to ensure safe equipment operation.

– Smoke Extraction and Cooling Systems: Increase fans and air filtration systems to improve ventilation and smoke extraction, maintaining a stable internal temperature.

II. Software Updates

1.Control System Firmware Update:

– Regularly check and upgrade the control system’s firmware to ensure optimal stability and compatibility with the latest version.

– Use official firmware provided by the equipment manufacturer to avoid compatibility issues caused by unofficial versions.

2.Temperature Curve Optimization:

– Upgrade the operating system to support various preset and custom temperature curves, meeting the temperature requirements of different solders and components.

– Optimize temperature settings during the preheating, heating, and cooling phases through curve programming to improve the success rate of soldering and desoldering.

3.Automation and Data Analysis:

– Utilize more advanced control system software to support automated operational processes, reducing human errors.

– Record and analyze historical temperature curves and operational data to identify soldering and desoldering issues and optimize operations.

III. Strategies for Updating and Upgrading

1.Equipment Needs Assessment:

– Evaluate whether hardware or software updates are necessary based on the current performance and production requirements of the infrared desoldering station.

2.Communication with the Manufacturer:

– Consult with the equipment manufacturer before upgrading to obtain professional advice and ensure compatibility between all replaced or upgraded components and software with the existing system.

3.Operator Training:

– Provide training to operators after updates and upgrades to familiarize them with the new equipment and system operating procedures, avoiding operational errors due to unfamiliarity.

4.Step-by-Step Upgrading:

– Perform upgrades in stages, first testing the stability of the new system to ensure there are no compatibility issues with other components before full implementation.

IV. Summary

Updating and upgrading the infrared desoldering station system is crucial to maintain efficient and stable equipment operation. Hardware improvements, such as upgrades to the infrared emitter, temperature sensors, and control panel, can enhance the system’s heating efficiency and control accuracy. Software updates, including firmware, temperature curve optimizations, and automation control system enhancements, further improve operational convenience and data analysis capabilities. By adopting a reasonable upgrade strategy, the infrared desoldering station system can evolve in sync with production demands, meeting higher quality and efficiency requirements.