SK-YJ000RFSHY-KP 100046

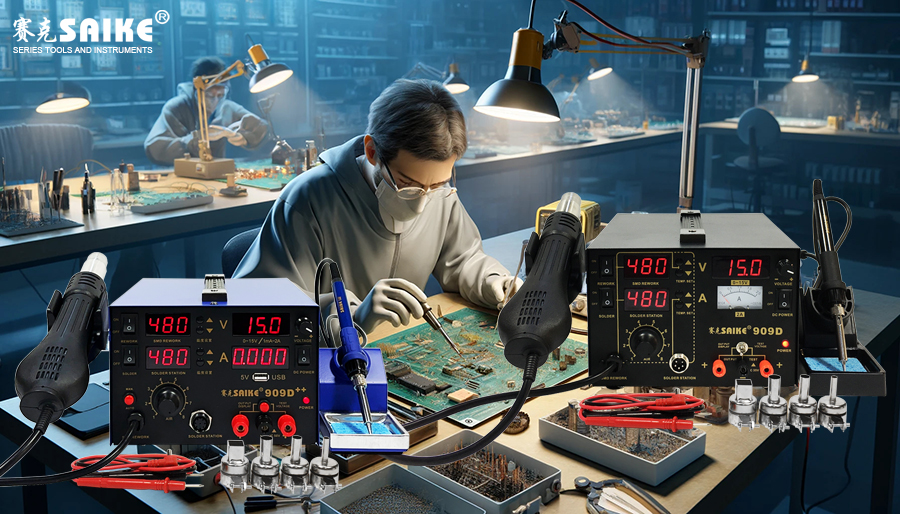

When using a hot air rework station, soldering station, and DC stabilized power supply for the desoldering and circuit repair of electronic components, some common faults may arise, such as cold solder joints, poor solder joints, and component damage. These issues can not only affect the repair outcome but also potentially cause equipment malfunction or safety hazards. This article analyzes the reasons for these common faults and provides corresponding troubleshooting methods.

I. Cold Solder Joints

1.Manifestations and Causes

– Manifestations: The circuit functions intermittently, and its status changes after slight tapping on the circuit board. Voltage instability at certain points during measurements.

– Causes:

– Insufficient soldering temperature, preventing the solder from fully melting.

– Inadequate soldering time, resulting in incomplete solder coverage of the pads and pins.

– Presence of oxides or impurities on the soldering surface, affecting solder adhesion.

2.Troubleshooting Methods

– Inspection and Resoldering: Use the soldering station to reheat the cold solder joints, ensuring that the solder fully melts and covers the solder pads and pins.

– Cleaning the Soldering Surface: Utilize alcohol and a brush to clean the soldering surface, removing oxides and impurities.

– Appropriate Temperature Increase: Raise the soldering temperature suitably based on the component’s heat resistance to ensure the solder melts adequately.

II. Poor Solder Joints

1.Manifestations and Causes

– Manifestations: The solder joint surface is uneven, with pores, cracks, irregular shapes, and poor electrical performance.

– Causes:

– Excessively high or low soldering temperature.

– Poor quality or improper use of solder.

– Inadequate soldering time control, leading to incompletely cooled solder joints.

2.Troubleshooting Methods

– Adjusting the Soldering Temperature: Set the soldering station temperature to an appropriate range (typically 350-400℃) based on the solder type and component requirements.

– Using High-Quality Solder: Select good quality solder, ensuring its melting point and fluidity are suitable for the current operation.

– Controlling the Soldering Time: Avoid prolonged heating, maintain solder joint stability after soldering, and allow it to cool naturally.

III. Component Damage

1.Manifestations and Causes

– Manifestations: Burned or deformed component appearance, functional failure, and abnormal electrical parameters.

– Causes:

– Excessively high temperature of the hot air rework station or soldering station, causing component damage due to prolonged heating.

– Inappropriate output voltage or current settings of the DC stabilized power supply, exceeding the component’s tolerance range.

– Mechanical damage, such as bent or broken component pins due to improper handling.

2.Troubleshooting Methods

– Correct Temperature Setting: Set the appropriate temperature for the hot air rework station and soldering station based on the component’s heat resistance (typically 300-350℃ for hot air and 350-400℃ for the soldering station).

– Calibrating the Stabilized Power Supply: Ensure the output voltage and current of the DC stabilized power supply are set within the component’s rated range. Perform calibration and testing before use.

– Careful Handling: Use tools like tweezers to carefully handle components during desoldering and installation, avoiding excessive force that could cause mechanical damage.

IV. Specific Fault Case Studies

1.Case Study 1: Circuit Instability Caused by Cold Solder Joints

Problem Description

A circuit board frequently experiences intermittent faults during operation, and the problem improves or deteriorates when lightly tapped.

Analysis

Inspection reveals the presence of cold solder joints on a resistor, with an uneven solder joint surface and incomplete solder coverage.

Treatment Methods:

– Use the soldering station to reheat the affected solder joint, ensuring adequate solder melting.

– Add a suitable amount of solder to ensure even coverage of the solder pad and resistor pins.

– Clean the soldering surface to remove impurities that may affect soldering quality.

2.Case 2: Poor soldering joints lead to poor electrical performance

Problem Description

An replaced IC behaves unstably during operation, and there are large voltage fluctuations when measuring its pins.

Analysis

Upon inspection, it was found that several soldering joints on the IC had pores on the surface and irregular shapes, resulting in poor electrical performance.

Treatment Methods:

– Adjust the soldering station temperature to a range suitable for IC soldering (350-370℃).

– Use high-quality solder to re-solder the IC pins, ensuring smooth and full soldering joints.

– Keep the soldering joints stable after soldering and allow them to cool naturally to avoid the formation of pores.

3.Case 3: Component damage leads to circuit failure

Problem Description

A capacitor on a certain circuit board fails to work properly after replacement, and there are burn marks around the capacitor.

Analysis

The possible reason is that the temperature setting of the hot air soldering station is too high, and prolonged heating leads to capacitor damage.

Treatment Methods:

– Set the temperature of the hot air soldering station between 300-350℃ to avoid excessive temperature.

– Replace the capacitor with a new one, minimizing the heating time during operation and completing the soldering quickly.

– Test the replaced capacitor to ensure it is working properly.

V. Summary

When using a hot air soldering station, soldering station, and DC stabilized power supply for the disassembly and soldering of electronic components and circuit repairs, common failures such as cold solder joints, poor soldering joints, and component damage may affect the quality of repairs. By carefully analyzing the causes of these failures and taking corresponding treatment methods, these problems can be effectively solved, improving the repair effect. Mastering the correct operating procedures and precautions, and regularly maintaining tools and equipment, will help ensure the smooth progress of electronic component soldering and circuit repairs.