SK-YJ000HWXCHT-KP 100009

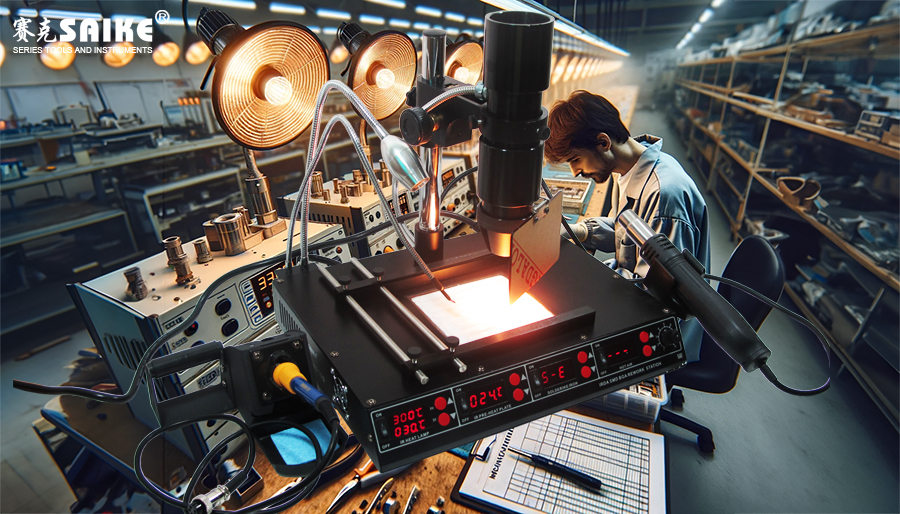

The infrared desoldering station is a device used for precision soldering and desoldering in electronic manufacturing and repair. Due to its efficient and accurate heating capabilities, the infrared desoldering station can handle high-density and complex packaged components. However, to maintain the optimal performance of the equipment and extend its service life, regular maintenance and cleaning are essential. This article will detail the routine maintenance and cleaning strategies for the infrared desoldering station to ensure its stable and efficient operation.

I. Daily Maintenance and Inspection

1.Power Supply and Cables:

– Regularly inspect the integrity of the power cord and plug to ensure there are no broken, frayed, or exposed wires.

– Ensure that the power socket is functioning properly and equipped with necessary leakage protection and overload prevention measures.

2.Temperature Control and Sensors:

– Check the working status of the temperature sensor and controller to ensure accurate temperature display.

– Regularly calibrate the temperature sensor and controller to maintain precise control during the heating process.

3.Infrared Lamps and Heating Elements:

– Inspect the infrared lamps or other heating elements for integrity and clear any dust or impurities from the lamps to ensure efficient emission.

– Regularly replace aging or damaged lamps and heating elements to maintain optimal heating performance.

4.Fans and Cooling:

– If the infrared desoldering station is equipped with fans or a cooling system, regularly inspect the fan’s working status and clear any dust from the fan blades.

5.Control Panel and Buttons:

– Check the proper functioning of the control panel, buttons, and display to ensure responsive operation.

– Clean the panel and buttons to maintain a tidy and readable interface.

II. Regular Cleaning and Maintenance

1.Cleaning Infrared Lamps and Reflectors:

– Use a lint-free cloth or soft brush to clean the infrared lamps and reflectors, ensuring they are dust-free and have optimal reflectivity.

– If there are stubborn stains on the lamps and reflectors, use a small amount of non-corrosive cleaner for cleaning.

2.Cleaning the Work Surface:

– Clean the work surface with a lint-free cloth or soft brush to remove welding slag and impurities left during the welding process, ensuring stability and durability.

– If the work surface is contaminated with solder or other pollutants, use a suitable solvent for cleaning.

3.Equipment Housing and Vents:

– Clean the equipment housing and vents with a dry or lint-free cloth to ensure a tidy appearance and dust-free vents.

4.Lubricating Moving Parts:

– If the infrared desoldering station includes moving mechanical parts (such as clamps, stands, etc.), lubricate them regularly to prevent mechanical wear.

III. Maintenance Logs and Training

1.Keeping Maintenance Logs:

– Establish and maintain a maintenance log to record the time, content, and identified issues for each maintenance activity, allowing easy tracking of the equipment’s operational status.

– Maintenance logs can help identify long-term issues and develop more reasonable maintenance plans.

2.Operation and Maintenance Training:

– Operators and maintenance personnel should receive professional training on how to operate the infrared desoldering station correctly and understand the steps and precautions for maintenance and cleaning.

IV. Conclusion

Routine maintenance and cleaning of the infrared desoldering station are crucial steps to ensure stable equipment operation and extend its service life. By regularly inspecting the power supply, temperature control, infrared lamps, and control panel, promptly cleaning heating elements and the work surface, and keeping the equipment lubricated and tidy, the infrared desoldering station can maintain optimal performance in electronic repair and production. Establishing maintenance logs and receiving professional training are also essential measures to improve equipment management.