SK-YJ000RFSHY-KP 100019

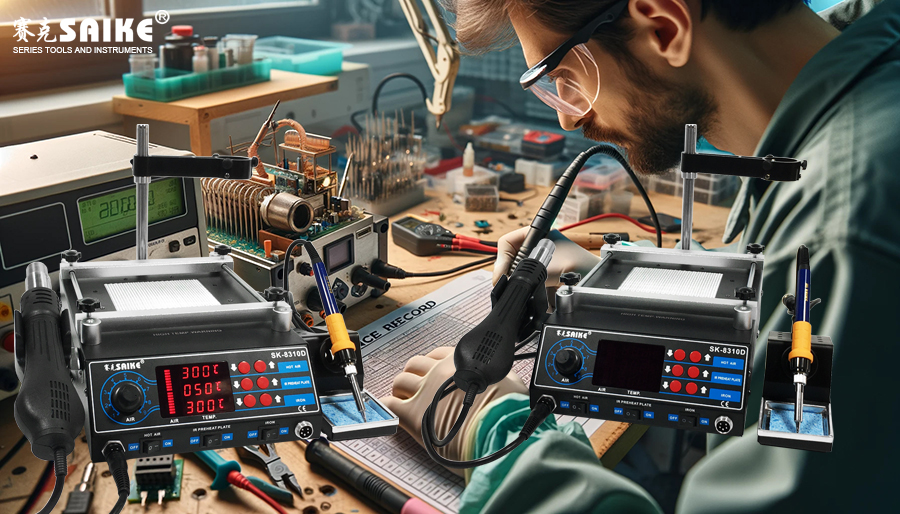

Regular maintenance of the hot air soldering station is crucial to ensure the long-term efficient operation and safety of the equipment. This article will introduce in detail the method of developing a regular maintenance plan for the hot air soldering station and provide a template for recording maintenance work.

I. Regular Maintenance Plan

1.Daily Inspection

The main item of the daily inspection is to ensure the basic function and safety of the equipment.

– Appearance inspection:

– Check the equipment enclosure for damage or abnormalities.

– Clean dust and debris from the equipment surface.

– Power inspection:

– Ensure that the power cord and plug are not damaged or overheating.

– Check that the power socket and cable connections are secure.

– Equipment operation:

– Start the equipment to ensure the fan is operating normally without abnormal noise.

– Set and test the temperature to confirm that the temperature controller is working properly.

2.Weekly Inspection

The weekly check item includes a more detailed inspection of the internal components.

– Nozzle inspection:

– Clean the nozzle to ensure there is no blockage or carbon deposition.

– Check the nozzle for cracks or wear and replace it immediately if damaged.

– Fan inspection:

– Check the fan blades for dust and debris, and clean them with a small brush.

– Start the equipment to check if the fan is running smoothly.

– Electrical connection inspection:

– Check the internal wires and connectors for looseness or aging.

3.Monthly Inspection

Monthly inspection items include deep cleaning of equipment and functional testing.

– Heating element inspection:

– Use a multimeter to measure the resistance value of the heating element to ensure it is within the normal range.

– Visually inspect the heating element for burning or breakage.

– Temperature controller inspection:

– Test the accuracy of the temperature controller’s readings and calibrate if necessary.

– Sensor inspection:

– Visually inspect the sensor’s appearance to ensure no damage.

– Test the sensor data feedback for accuracy and stability.

4.Quarterly Inspection

The items examined quarterly include a complete inspection of the equipment and necessary maintenance.

– Comprehensive cleaning:

– Clean all internal components of the equipment to ensure they are dust-free.

– Check and clean the air ducts and heat dissipation holes.

– Lubrication maintenance:

– Add lubricating oil to the fan bearings to keep the fan running smoothly.

– Equipment calibration:

– Fully calibrate the temperature controller and sensor to ensure their accuracy.

– Replacement of wearing parts:

– Regularly replace wearing parts such as heating elements and sensors according to equipment usage.

5.Annual Inspection

The annual inspection includes comprehensive performance testing and maintenance of the equipment.

– Comprehensive performance test:

– Conduct a comprehensive test on the equipment to ensure all functions are normal.

– Check the overall operating status of the equipment and assess whether major repairs or replacements are needed.

– Maintenance record assessment:

– Review the maintenance records of the whole year, analyze equipment usage and maintenance effects.

– Develop a maintenance plan for the next year to improve and optimize the maintenance process.

II. Maintenance Record Template

To effectively track and record each maintenance activity, the following template can be used:

Maintenance Record Table

|

Date |

Maintenance Item |

Specific Operation |

Problems Found |

Measures Taken |

Responsible Person |

Remarks |

|

yyyy/mm/dd |

Daily Inspection |

Clean equipment surface, check power connection |

None |

None |

Zhang San |

|

|

yyyy/mm/dd |

Weekly Inspection |

Clean nozzle, check fan operation |

Slight wear on the nozzle |

Replace nozzle |

Li Si |

|

|

yyyy/mm/dd |

Monthly Inspection |

Check heating element resistance, calibrate temperature controller |

High heating element resistance |

Replace heating element |

Wang Wu |

|

|

yyyy/mm/dd |

Quarterly Inspection |

Lubricate fan bearings, comprehensive equipment cleaning |

Slight abnormal noise from the fan |

Add lubricating oil, clean fan blades |

Zhao Liu |

|

|

yyyy/mm/dd |

Annual Inspection |

Comprehensive performance test, review maintenance records |

None |

Develop a new annual maintenance plan |

Zhou Qi |

Maintenance Record Detailed Description:

In each maintenance record table, the specific maintenance operations and problems found can be described in detail:

Maintenance Record Example:

– Date: 2024/05/17

– Maintenance Item: Weekly Inspection

– Specific Operation: Clean nozzle, check fan operation

– Problems Found: Slight wear on the nozzle, fan operation is normal

– Measures Taken: Replace nozzle

– Responsible Person: Li Si

– Remarks: The replaced nozzle is operating normally without abnormalities.

III. Summary

Regular maintenance of the hot air soldering station is the key to ensuring efficient and safe equipment operation. Through detailed maintenance plans and records, the equipment can be systematically inspected and maintained, potential problems can be discovered and addressed in a timely manner, equipment lifespan can be extended, and work efficiency can be improved. It is hoped that the plan and record template provided in this article can help electronic repair personnel better maintain the hot air soldering station and ensure its long-term stable operation.