SK-YJ000YRT-KP 100015

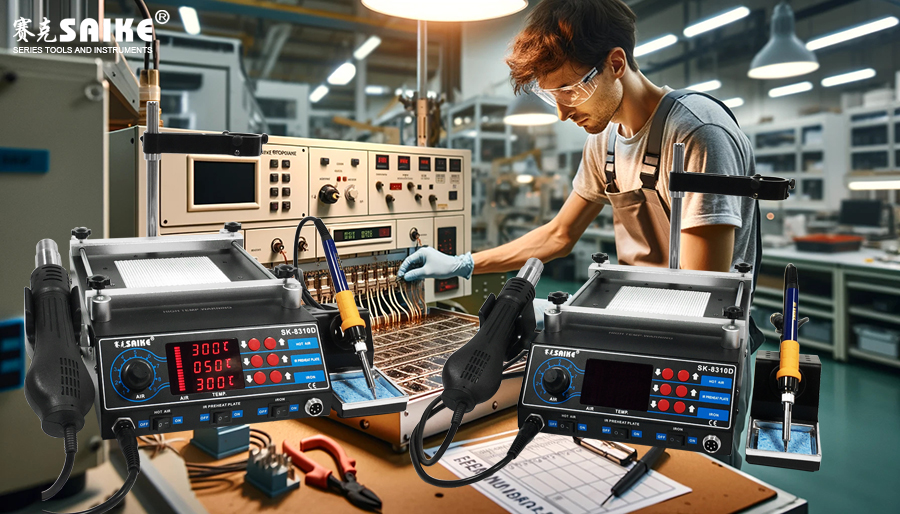

The preheating platform is a crucial equipment in electronic manufacturing and maintenance, used for heating circuit boards and other electronic components in preparation for soldering. To ensure the performance and safety of the preheating platform, regular inspection and maintenance are essential. This article will detail the regular inspection and maintenance procedures for the preheating platform, aiming to assist technicians in effectively managing and maintaining this critical equipment.

I. The Importance of Regular Inspection of Preheating Platform

1.Ensuring Equipment Performance: Regular inspections help to confirm that the equipment is operating according to the manufacturer’s specifications, ensuring heating efficiency and uniformity.

2.Preventing Failures: Inspections can detect potential issues early, preventing small problems from escalating into expensive repairs.

3.Extending Equipment Lifespan: Proper maintenance can significantly extend the lifespan of the equipment, reducing the need for frequent replacements.

II. Regular Inspection Procedures for Preheating Platform

1.Checking Power Supply and Cables

– Confirm that the power cord and plug are damage-free, without wear or exposed wires.

– Inspect cables for secure fastening and check for loose or corroded connections.

2.Inspecting Heating Elements

– Regularly check if the heating elements are functioning properly, without breaks or noticeable wear.

– For infrared or hot air preheating platforms, inspect the heating elements for uniform heating, and the absence of abnormal hot spots or unheated areas.

3.Examining the Control System

– Test all buttons and switches on the control panel, ensuring their responsiveness and proper function.

– Check the accuracy of the temperature controller and sensor, calibrating if necessary.

4.Inspecting Structural Integrity

– Examine the equipment housing, supports, and mounting surfaces for cracks, deformations, or loose screws.

– Ensure the stability of the equipment, checking for any wobbling or tilting.

5.Cleaning the Equipment

– Regularly clean the equipment’s surface and interior, removing dust and other contaminants.

– Use suitable cleaners for the control panel and housing, avoiding strong chemicals.

III. Maintenance Suggestions for Preheating Platform

1.Regular Maintenance Plan

– Develop and follow a regular maintenance plan based on equipment usage frequency and manufacturer recommendations.

– Keep records of maintenance dates, tasks performed, and issues found for easy tracking of equipment status.

2.Replacing Worn Parts

– Regularly inspect and replace worn components like damaged heating elements or malfunctioning controllers.

– Use only original or high-quality compatible spare parts for replacements.

3.Training Operators

– Ensure that all operators receive proper training on how to correctly operate and maintain the preheating platform.

– Provide regular safety and maintenance training, updating operators on the latest information and techniques related to equipment operation.

4.Safety Checks

– Conduct a quick but thorough safety inspection before each use, ensuring no potential safety hazards are overlooked.

IV. Conclusion

By implementing regular inspection and maintenance plans, not only can the operational efficiency and safety of the preheating platform be improved, but long-term operating costs can also be reduced. Effective maintenance is key to ensuring the reliability of the preheating platform, crucial for maintaining production quality and avoiding delays. These best practices will assist any facility management team in effectively managing their preheating equipment, ensuring it remains in optimal condition.