SK-YJ000YRT-KP 100025

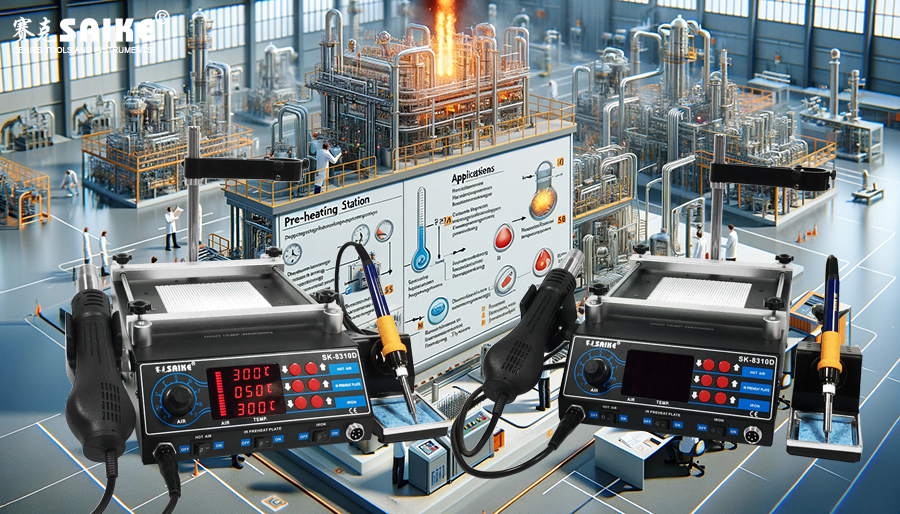

The preheating station is an indispensable tool in electronic manufacturing and maintenance. It optimizes the soldering and assembly processes by preheating circuit boards or components in advance, thereby reducing production defects. This article summarizes important course knowledge points about the preheating station, including its working principle, applications, operation techniques, maintenance, and troubleshooting methods. The aim is to provide comprehensive guidance for technicians who use and maintain preheating stations.

I. Working Principle of the Preheating Station

1.Basic Function:

– The preheating station is mainly used to preheat circuit boards before soldering or other heat treatment processes, reducing thermal stress, preventing warping, and improving soldering quality.

2.Heating Technology:

– Common heating technologies include infrared heating, hot air heating, and electric heating wire heating. Each technology has different thermal efficiencies and application characteristics.

3.Temperature Control:

– The preheating station is usually equipped with temperature sensors and a control system that can set and monitor the heating temperature, ensuring the uniformity and accuracy of the heating process.

II. Applications of the Preheating Station

1.Electronic Manufacturing:

– Preheat PCBs (Printed Circuit Boards) in SMT (Surface Mount Technology) and PTH (Pin Through Hole) to improve soldering quality and reduce soldering defects.

2.Repair and Rework:

– Preheat damaged circuit boards during electronic equipment repair to facilitate the removal and re-soldering of components, reducing the risk of further damage.

3.Industrial Applications:

– Preheat materials in the plastics, metal processing, and composites industries to optimize processing effects and physical properties.

III. Operation Techniques and Best Practices

1.Temperature Setting:

– Select appropriate preheating temperatures and times based on the characteristics of the material and components. Avoid overheating or insufficient heating.

2.Uniform Heating:

– Ensure that the heating elements of the preheating station can uniformly heat the entire work area, paying special attention to large or irregularly shaped circuit boards.

3.Safe Operation:

– Follow operating procedures, use personal protective equipment, and ensure safe operation of the preheating station in a safe environment.

IV. Maintenance and Troubleshooting

1.Routine Maintenance:

– Regularly clean the preheating station and check the integrity of power cords, heating elements, and temperature sensors.

2.Troubleshooting:

– Learn to recognize common signs of failure, such as the preheating station not heating or temperature control malfunctioning, and master basic troubleshooting methods.

3.Professional Repair:

– For complex failures, contact professional repair personnel or the manufacturer for repairs.

V. Summary

The preheating station is a key equipment to improve the quality of electronic manufacturing and maintenance. By understanding its working principle, mastering the correct operation methods, and performing regular maintenance, the usage effect of the preheating station can be maximized, and its service life can be extended. Improving troubleshooting ability is also an important factor in ensuring production continuity and reducing operating costs. It is hoped that through the summary of knowledge points in this article, operators can be more proficient in using the preheating station, bringing higher efficiency and quality to the electronic manufacturing and maintenance industry.