SK-YJ000HWXCHT-KP 100008

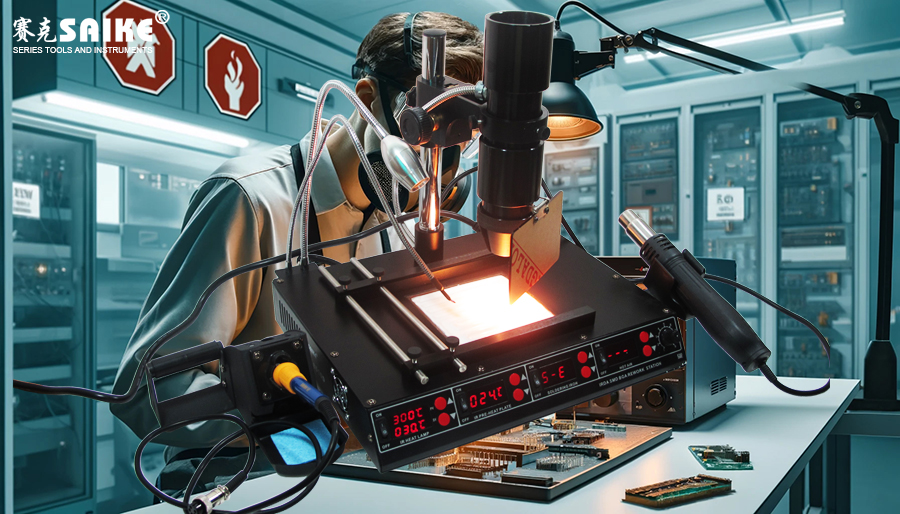

Infrared desoldering stations are highly efficient electronic repair equipment, especially suitable for soldering and desoldering high-density electronic components. However, the infrared heating process can generate high temperatures and radiation, and may release harmful gases. To ensure the safety of operators, it is necessary to take appropriate protective measures and wear personal safety equipment. This article will introduce the protective measures and personal safety equipment for infrared desoldering stations in detail, helping operators work safely and efficiently.

I. Protective Measures for Infrared Desoldering Stations

1.Equipment Ventilation and Exhaust Systems:

– When operating the infrared desoldering station, it is necessary to ensure that the equipment is installed in a well-ventilated area to facilitate the exhaust of smoke and harmful gases generated during the heating process.

– To further reduce the contaminant content in the air, it is recommended to install an exhaust system or suction device to keep the air in the work area clean.

2.Safety Devices of the Equipment:

– Overheating Protection: The infrared desoldering station should have overheating protection to ensure automatic power-off when reaching the safe temperature threshold, preventing equipment and circuit board damage.

– Emergency Stop Button: The equipment should be equipped with a conspicuous emergency stop button to facilitate rapid power cutoff in emergency situations, ensuring operational safety.

3.Equipment Stability:

– Ensure that the infrared desoldering station is placed on a stable workbench to avoid vibration and slippage during operation.

– Electronic components should be fixed on the workbench or fixture during heating to prevent accidental movement leading to misoperation.

4.Temperature Monitoring and Control:

– Use high-precision temperature sensors to monitor the temperature of solder joints and heating elements, ensuring they always stay within the set temperature range.

– Regularly calibrate the temperature control system to prevent overheating or insufficient heating due to inaccurate data.

II. Personal Safety Equipment

1.Protective Glasses or Masks:

– Wear specialized protective glasses or masks to protect the eyes from infrared radiation and splashes generated during heating.

– Choose products that meet industry standards to ensure they can prevent infrared radiation from entering the field of vision.

2.Protective Gloves:

– Wear high-temperature resistant protective gloves to prevent burns when touching high-temperature and heating elements.

3.Protective Clothing:

– Wear anti-static, high-temperature resistant protective clothing to avoid direct exposure of the body to high-temperature areas and prevent electrostatic damage to electronic components.

4.Respiratory Protective Equipment:

– Use gas masks or other respiratory protective equipment to protect operators from harmful smoke and gases generated during the heating process.

III. Summary

Protective measures and personal safety equipment for infrared desoldering stations are crucial to ensure operator safety and equipment effectiveness. Through a comprehensive ventilation and exhaust system, safety devices, stability measures, temperature monitoring, and control, operational risks can be effectively reduced. Meanwhile, operators should wear appropriate protective glasses, gloves, protective clothing, and respiratory protective equipment to avoid damage to the body caused by high temperatures, radiation, and harmful gases generated during the infrared heating and desoldering processes. Through a comprehensive protective strategy, the operational safety of infrared desoldering stations can be ensured, and production efficiency can be improved.