SK-YJ000YRT-KP 100023

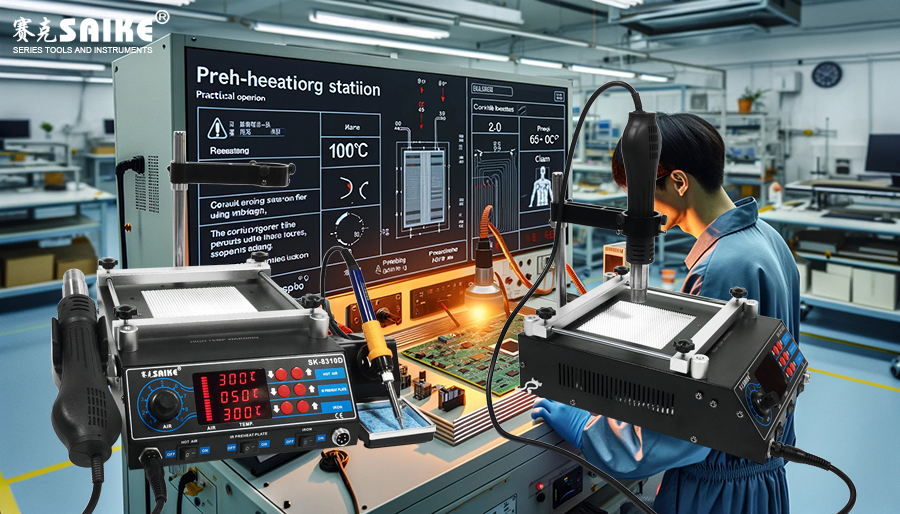

The preheating station is an indispensable equipment in the electronic assembly and maintenance industry, used to preheat circuit boards before soldering to reduce thermal stress and improve soldering quality. Mastering the correct operation of the preheating station is crucial to ensure product quality and production efficiency. This article provides detailed practical operation and technical guidance for the preheating station, aiming to help technicians use it more effectively.

I. Preparation before Operating the Preheating Station

1.Understand Equipment Specifications:

– Familiarize yourself with the functions, operation interface, and safety features of the preheating station. Read the operating manual provided by the manufacturer to understand the basic operation procedures and safety precautions of the equipment.

2.Check Equipment Status:

– Ensure that the preheating station is clean and dust-free, and the power cord and plug are intact.

– Check the heating plate and temperature sensor for any obvious damage or wear.

3.Configure the Working Environment:

– Place the preheating station on a stable, level workbench with sufficient space around it for safe operation.

– Ensure good ventilation to remove any smoke or gases that may be produced.

II. Setting Preheating Station Parameters

1.Set Preheating Temperature:

– Adjust the preheating temperature according to the material and component characteristics of the circuit board. Typically, the preheating temperature is set between 100°C and 150°C.

2.Set Preheating Time:

– Adjust the preheating time based on the size and thickness of the circuit board. Generally, the preheating time ranges from 5 to 10 minutes.

3.Select Heating Mode:

– If the preheating station supports multiple heating modes, choose the one most suitable for the current task (such as full heating, local heating, or gradual heating).

III. Operation Process

1.Start the Preheating Station:

– Turn on the power and activate the preheating station according to the equipment’s startup procedure.

– Monitor the equipment during startup to ensure all systems are running normally.

2.Place the Circuit Board:

– Place the circuit board to be heated flat in the heating area of the preheating station, ensuring no obstacles between the board and the heating element.

3.Monitor the Heating Process:

– Use a temperature sensor or infrared thermal imager to monitor the temperature of the circuit board in real-time, ensuring uniform heating and not exceeding the set maximum temperature.

4.Complete Preheating:

– Once the predetermined time is reached, turn off the preheating station and allow the circuit board to cool naturally to room temperature to avoid thermal stress caused by rapid cooling.

IV. Post-Operation Inspection and Maintenance

1.Check Circuit Board Status:

– After preheating, inspect the circuit board for warping or other thermal damage.

– Perform necessary functional tests on the circuit board to ensure all components are functioning normally.

2.Clean and Maintain the Preheating Station:

– Regularly clean the preheating station, especially the heating plate and sensors, to remove dust and residue.

– Follow the manufacturer’s recommendations for routine maintenance of the preheating station.

V. Summary

Effective operation of the preheating station requires a deep understanding of the equipment and strict adherence to operating procedures and safety guidelines. By practicing the aforementioned operational drills and technical guidance, technicians can become more proficient in using the preheating station, thereby improving soldering quality, reducing production defects, and ensuring efficient and safe electronic manufacturing and maintenance work. Proper preheating operation is a crucial step in improving the quality and reliability of electronic assembly.