SK-YJ000RFSHY-KP 100017

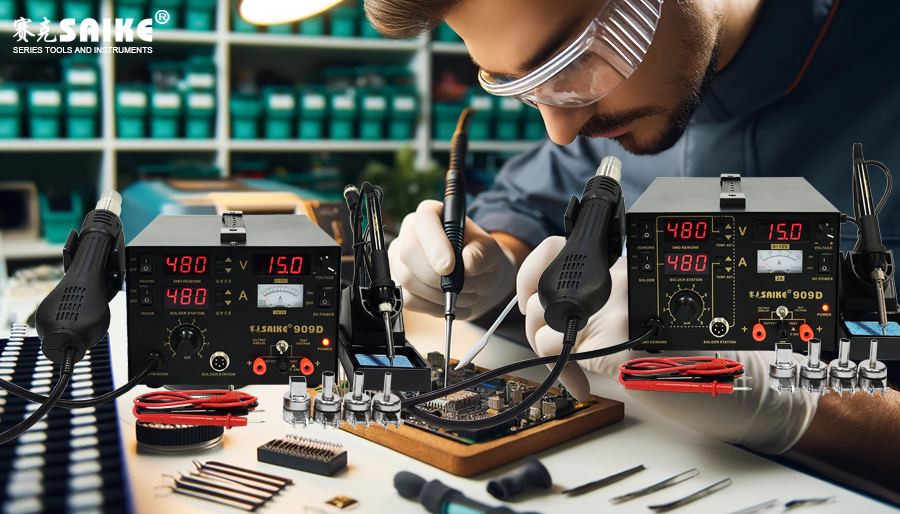

The hot air rework station plays a crucial role in electronic repair and manufacturing processes, and its nozzle is one of the key components that directly affect soldering and desoldering results. To ensure the efficient and safe operation of the hot air rework station, regular cleaning and nozzle replacement are essential. This article will detail the methods for cleaning and replacing the nozzle of a hot air rework station.

I. Nozzle Cleaning Method

1.Prepare Tools and Materials

– Protective gloves

– Protective glasses

– Soft cloth or lint-free cloth

– Cotton swabs

– Small brush (e.g., toothbrush)

– Alcohol or specialized cleaner

– Tweezers

2.Cleaning Steps

– Ensure Safety

– Turn off the power: Make sure the hot air rework station is turned off and unplugged before cleaning the nozzle.

– Allow the equipment to cool: Wait for the equipment to cool completely to prevent burns.

– Remove the Nozzle

– Wear protective gear: Put on protective gloves and glasses to safeguard your hands and eyes.

– Detach the nozzle: Use tweezers or manual rotation to remove the nozzle from the hot air gun. Different models of hot air rework stations may require different tools and methods, so refer to the equipment manual.

– Clear Surface Dirt

– Wipe the exterior: Use a soft or lint-free cloth to wipe the outside of the nozzle, removing dust and dirt from the surface.

– Clean the interior: Gently scrub the inside of the nozzle with a small brush to eliminate accumulated solder residue and oxides.

– Deep Cleaning

– Use cotton swabs: Dip a cotton swab in a small amount of alcohol or specialized cleaner and use it to wipe the inside of the nozzle, further removing stubborn dirt.

– Soak cleaning: If there is a lot of buildup inside the nozzle, you can soak it in alcohol or cleaner for a few minutes before cleaning with a small brush and cotton swabs.

– Inspection and Installation

– Inspect the nozzle: After cleaning, check the nozzle for cracks or wear to ensure it’s intact.

– Reinstall: Reinstall the cleaned nozzle onto the hot air gun, ensuring it’s securely fastened.

II. Nozzle Replacement Method

1.Prepare Tools and Materials

– Protective gloves

– Protective glasses

– Tweezers or appropriate removal tools

– New hot air gun nozzle

2.Replacement Steps

– Ensure Safety

– Turn off the power: Make sure the hot air rework station is turned off and unplugged before replacing the nozzle.

– Allow the equipment to cool: Wait for the equipment to cool completely to prevent burns.

– Remove the Old Nozzle

– Wear protective gear: Put on protective gloves and glasses to safeguard your hands and eyes.

– Detach the old nozzle: Use tweezers or manual rotation to remove the old nozzle from the hot air gun. Refer to the equipment manual for the correct removal method.

– Inspect the Interface

– Clean the interface: Use a soft or lint-free cloth to clean the interface on the hot air gun, ensuring it’s dust-free and residue-free.

– Inspect the interface: Check the interface for damage or wear to ensure it’s intact.

– Install the New Nozzle

– Choose a suitable nozzle: Select a nozzle of the appropriate model and specifications based on your needs.

– Install the new nozzle: Align the new nozzle with the interface, gently rotate or press it into place, ensuring it’s securely mounted on the hot air gun.

– Test the Nozzle

– Power-on test: Reconnect the power, start the hot air rework station, and set the appropriate temperature and airspeed.

– Check nozzle operation: Observe the new nozzle’s performance, ensuring the airflow is even and the temperature is stable.

III. Conclusion

Regular cleaning and replacing the nozzle of the hot air rework station are crucial measures to ensure the equipment’s efficient and safe operation. By adopting the correct cleaning methods, you can extend the nozzle’s lifespan and maintain the equipment’s good performance. Timely replacement of damaged or aging nozzles can prevent instability and potential hazards during operation. It is hoped that the cleaning and replacement methods provided in this article will assist electronic repair technicians in better maintaining and using the hot air rework station, ensuring work quality and safety.