SK-YJ000YRT-KP 100009

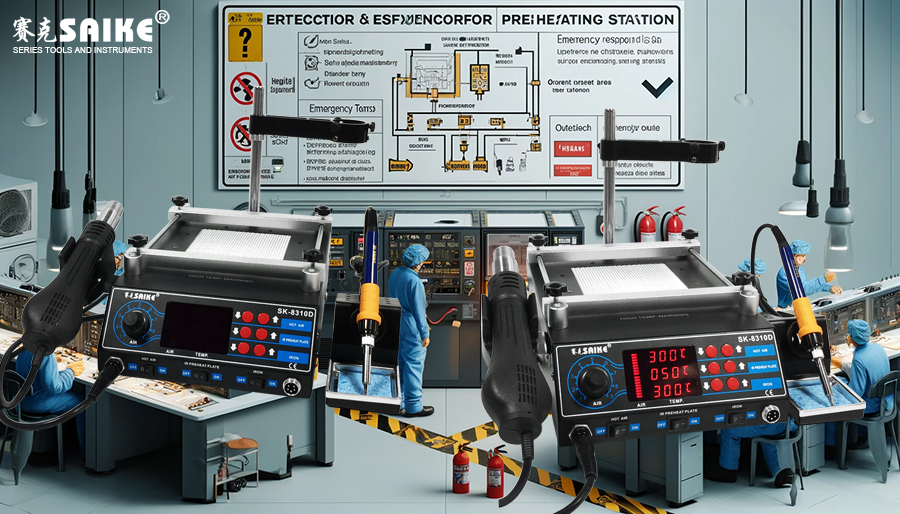

The preheating station is a commonly used equipment in the electronic manufacturing and maintenance industry, mainly used for preheating circuit boards or other electronic components for the soldering process. Although the preheating station is an important tool to improve soldering quality and efficiency, improper operation or inadequate equipment maintenance may lead to accidents. This article will explore how to prevent and handle accidents on preheating stations to ensure operational safety and equipment operating efficiency.

I. Preventive Measures

The key to preventing accidents on preheating stations lies in strict safety operating procedures, regular equipment maintenance, and comprehensive employee training.

1.Establish and comply with safety operating procedures:

– Develop detailed operating guidelines for the preheating station, clarifying operating steps, safety warnings, and emergency measures.

– Ensure that all operators receive appropriate training and pass the assessment before independently operating the preheating station.

2.Regular equipment maintenance and inspection:

– Regularly inspect the preheating station, including wires, heating elements, control systems, and ventilation systems, to ensure that all components are in good working condition.

– Replace any worn or damaged parts, clean accumulated dust and dirt, and avoid the risk of overheating and fire.

3.Install necessary safety devices:

– Equip with overheat protection devices and automatic power-off functions to prevent accidents when the equipment temperature abnormally rises.

– Install smoke detectors and fire alarm systems in the operating area to detect and handle fire accidents in a timely manner.

4.Proper work environment layout:

– Ensure that there is sufficient space and good ventilation around the preheating station, and keep flammable items away from high-temperature areas.

– Clarify the location of emergency exits and emergency stop switches to ensure that power can be quickly cut off and safe evacuation can be carried out in an emergency.

II. Emergency Response Measures

Even with careful preventive measures, accidents may still occur. Therefore, it is crucial to develop effective emergency response measures to minimize the consequences of accidents.

1.Incident response plan:

– Develop a detailed incident response plan, including initial response measures, notification processes, evacuation routes, and incident investigation procedures.

– Conduct regular emergency response drills to ensure that all employees understand the action guide in an emergency.

2.Emergency shutdown operation:

– Set up an emergency stop button in a prominent position in the operating area of the preheating station to ensure that the power can be immediately interrupted in case of an accident.

– Train all operators to recognize when emergency shutdown is needed and can be quickly implemented.

3.Fire response measures:

– Equip the operating area with fire extinguishers suitable for electrical fires, such as carbon dioxide or dry powder extinguishers, and regularly check their effectiveness.

– Train employees how to properly use fire extinguishers and handle initial fires.

4.Incident recording and review:

– Record detailed information about each incident, including the time, cause, affected equipment, response measures, and results.

– Regularly review and analyze incident records, evaluate the effectiveness of existing safety measures, and make adjustments if necessary.

III. Conclusion

Through strict preventive measures and effective emergency response plans, the safety risks in the operation of the preheating station can be significantly reduced. Regular equipment maintenance, employee safety training, and clear incident response guidelines are the keys to ensuring operational safety. Proper handling of emergencies can not only protect the safety of employees but also reduce equipment losses and ensure the continuity of production and maintenance operations.