SK-YJ000YRT-KP 100004

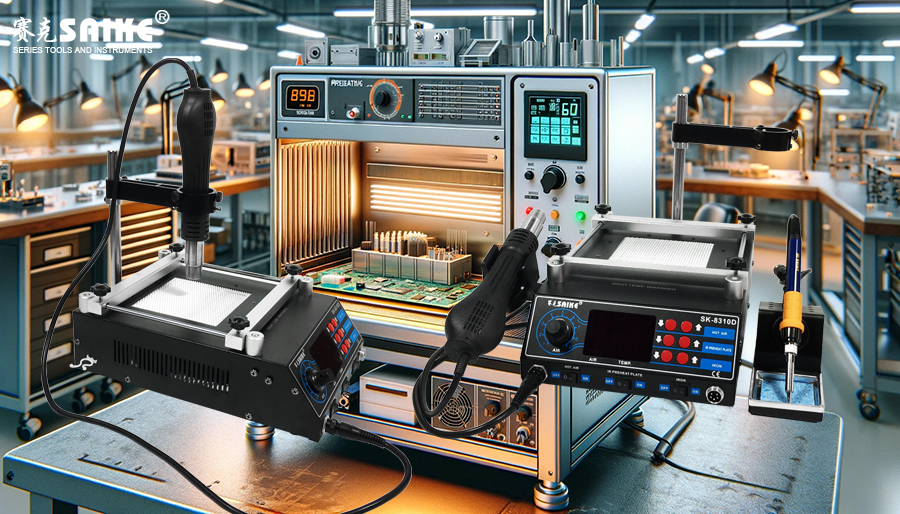

A preheating station is a device used in electronic manufacturing and repair work to preheat circuit boards and other components in advance, optimizing the soldering process and preventing damage caused by thermal stress. This equipment consists of multiple key components, each playing a vital role in ensuring the efficient operation of the entire device. This article will detail the main components of a preheating station and their functions.

I. Heating System

1.Heating Elements

– The heating element is the core component of the preheating station, typically consisting of electric heating wires, hot air generators, or infrared lamps, responsible for generating sufficient heat to preheat the circuit board or other components.

– Electric heating wire: Operates based on the principle of resistive heating, suitable for small or medium-sized preheating stations.

– Hot air generator: Uses a fan to blow hot air uniformly towards the work area, suitable for applications requiring uniform heating.

– Infrared lamp: Emits infrared radiation, suitable for applications requiring deep heating or heating large areas.

2.Temperature Control System

– The preheating station is equipped with a temperature controller, which usually includes a thermocouple, temperature sensor, and microprocessor control unit.

– The temperature control system can accurately measure and adjust the temperature of the heating element, ensuring temperature stability and uniformity during the preheating process.

II. Ventilation System

1.Fan

– For preheating stations using hot air heating, a fan is an essential component for evenly distributing hot air to the preheating area.

– The fan also helps cool the internal components, keeping the equipment operating at a safe temperature.

2.Vent

– The vent design ensures effective circulation of hot air, preventing overheating inside the equipment.

– Additionally, the vent design helps extract potentially harmful fumes and gases, protecting the health of operators.

III. Control System

1.Control Panel

– The control panel is the interface between the user and the preheating station, including control buttons or a touchscreen for temperature settings, timing functions, and other operating modes.

– Modern preheating stations may include program storage and recall functions on the control panel, making operation more convenient and precise.

2.Microprocessor

– The microprocessor is the brain of the preheating station’s control system, responsible for processing sensor data, executing user-set commands, and regulating the heating system and fan operation.

– Through software upgrades, the microprocessor can enhance the device’s functionality, providing more customized heating solutions.

IV. Structural Components

1.Workbench

– The workbench is a platform for placing circuit boards or components to be heated, usually made of high-temperature resistant materials such as ceramic or metal alloys.

– The design requires a flat workbench with good thermal conductivity to ensure heating uniformity.

2.Machine Body Shell

– The shell protects the internal components from external environmental influences while providing a stable supporting structure for the preheating station.

– The shell material needs to have good heat resistance and sufficient mechanical strength to adapt to various working environments.

V. Conclusion

Understanding the main components and their functions is crucial for selecting and maintaining preheating stations. Reasonable equipment configuration and maintenance can not only improve the efficiency of the preheating station but also extend its service life and ensure soldering quality. With technological advancements, the components of the preheating station are constantly evolving, making these devices more efficient, stable, and user-friendly.