SK-YJ000HWXCHT-KP 100006

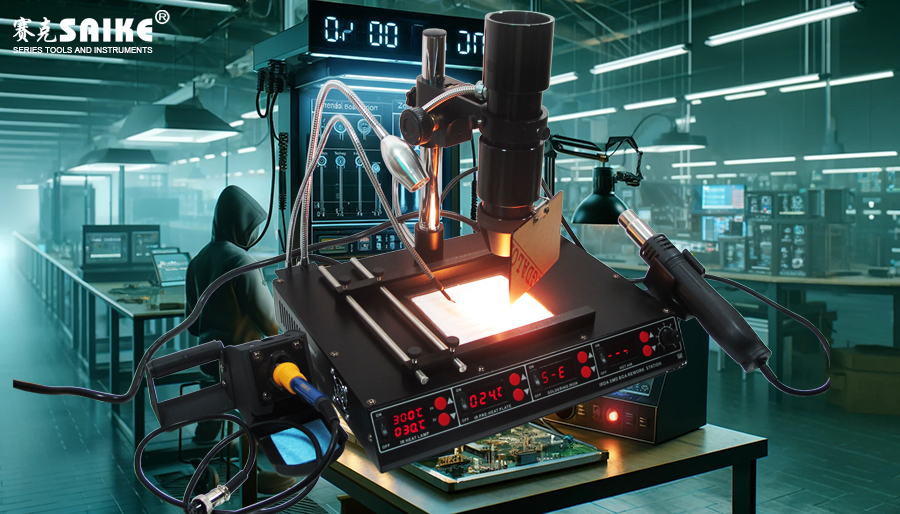

In electronic manufacturing and maintenance, the infrared desoldering station has become an ideal tool for welding and desoldering high-density and sensitive electronic components due to its precise heating control and flexibility. With the continuous development of technology, the infrared desoldering station has been equipped with more advanced functions, such as zone heating control and automation programs. This article will introduce these advanced functions in detail and elaborate on their importance and advantages in practical operations.

I. Zone Heating Control

1.Multi-zone heating principle:

– Multi-zone heating is a technology that independently controls the temperature of different areas on the circuit board or welding area. The infrared emitter adopts a partitioned design so that the heating elements in different areas can independently adjust the temperature and power.

2.Advantages:

– Precise control ensures that the temperature of each area is independently adjusted to provide a more precise heating effect. Uniform heating avoids welding defects caused by local overheating or cooling, improving welding quality and reliability. Zone control can better control the heating rate of different materials and components, reducing thermal stress and protecting multilayer circuit boards and sensitive components.

3.Application scenarios:

– Complex multilayer circuit boards, where each layer reacts differently to heat, and zone heating can ensure uniform heating. For high-density packaged components, local heating can prevent damage to adjacent sensitive components.

II. Automation Program

1.Programmable temperature curve:

– The infrared desoldering station is equipped with a programmable temperature control system. Users can preset the heating, constant temperature, and cooling curves according to the characteristics of specific components and solders. Through the built-in programming logic, the preset temperature curve can be repeatedly executed to ensure the consistency of welding and desoldering quality.

2.Automated operation process:

– According to the preset program, the infrared desoldering station can automatically complete the disassembly and welding process of components, including the preheating, heating, and cooling stages. The automation system can record temperature curves and welding data for quality control and analysis later.

3.Intelligent detection and calibration:

– Advanced automation programs can detect and calibrate temperature sensors and control systems to ensure real-time accuracy. When an abnormality is detected, the system can issue an alarm or stop automatically to protect the components and circuit boards.

III. Summary

In summary, the zone heating control and automation program of the infrared desoldering station represent the latest development in this technical field. Through multi-zone heating, precise temperature control of the circuit board and components can be achieved, improving the quality and consistency of welding. The automation program realizes the automatic control and data recording of the temperature curve through programming, which helps technicians to perform electronic maintenance work more efficiently and consistently. Mastering these advanced functions will help operators fully utilize the advantages of infrared desoldering stations in high-precision electronic maintenance and production.