SK-YJ000RFSHY-KP 100030

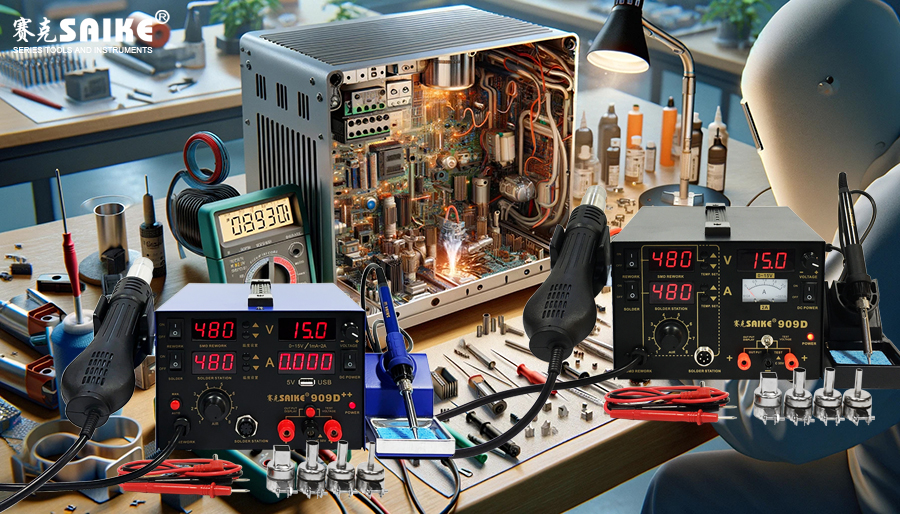

The welding station is a core equipment in electronic welding work, and the condition of its internal components directly affects the welding effect and operational safety. Regular inspection and maintenance of the internal components of the welding station are important steps to ensure the normal operation of the equipment and extend its service life. This article will introduce the inspection and maintenance methods of the internal components of the welding station in detail.

I. Steps for Inspecting Internal Components of the Welding Station

1.Safety Preparation

– Turn off the power: Before performing any inspection and maintenance, ensure that the welding station is turned off and unplugged.

– Cool down the equipment: Wait for the welding station to cool completely to avoid burns and damage to components.

2.Disassemble the Shell

– Use appropriate tools (such as screwdrivers) to disassemble the welding station shell and expose the internal components.

– Handle the removed screws and shell parts carefully to avoid loss or damage.

3.Check the Heating Elements

– Visual inspection: Check the heating elements for obvious signs of burning, cracks, or other damage.

– Resistance measurement: Use a multimeter to measure the resistance value of the heating elements to ensure they are within the normal range (refer to the welding station manual for parameters).

– Connection inspection: Check the wire connections of the heating elements to ensure they are secure without looseness or poor contact.

4.Check the Temperature Sensor

– Visual inspection: Check the temperature sensor surface for obvious damage or wear.

– Resistance measurement: Use a multimeter to measure the resistance value of the temperature sensor to ensure it is within the normal range.

– Position inspection: Ensure that the temperature sensor is correctly installed in the designated position and can accurately sense the temperature.

5.Check the Control Circuit

– Component inspection: Check the components on the circuit board (such as capacitors, resistors, diodes, etc.) for signs of burning, bulging, or looseness.

– Solder joint inspection: Check the solder joints on the circuit board for cracks, cold solder joints, or false solder joints.

– Power inspection: Check whether the output voltage of the power module is stable and meets the requirements of the welding station.

6.Check the Power Cord and Plug

– Visual inspection: Check the power cord for damage, aging, or exposed wires.

– Contact inspection: Check the contact between the plug and socket for looseness or overheating.

II. Methods for Maintaining Internal Components of the Welding Station

1.Cleaning

– Dust removal: Use compressed air or a soft brush to clean the dust inside the welding station, especially on the circuit board and heat dissipation components.

– Contact cleaning: Use anhydrous alcohol and cotton swabs to clean the solder joints and connectors on the circuit board to ensure good contact.

2.Lubrication

– Radiator maintenance: Add a moderate amount of lubricating oil to the radiator or fan components to ensure the normal operation of the cooling system.

– Moving parts: Check and lubricate all moving parts in the welding station to avoid jamming and wear.

3.Replacement of Aging Components

– Regular replacement: Regularly replace aging components (such as electrolytic capacitors, wiring terminals, etc.) according to equipment usage to ensure stable operation of the welding station.

– Spare parts reserve: Prepare commonly used spare parts (such as fuses, temperature sensors, etc.) for timely replacement.

4.Calibration

– Temperature calibration: Regularly use a temperature calibrator to calibrate the welding station to ensure accurate temperature control.

– Equipment calibration: Regularly perform equipment calibration and adjustment according to the recommendations in the user manual to ensure that all functions are normal.

III. Operating Specifications and Safety Precautions

1.Anti-static Measures

– When performing internal inspections and maintenance, use anti-static bracelets and anti-static mats to avoid electrostatic damage to components.

2.Recording and Tracking

– Record the situation of each inspection and maintenance, including the problems found and the measures taken, and establish equipment maintenance archives.

3.Regular Maintenance

– Develop a regular maintenance plan based on equipment usage frequency and working environment to ensure that the welding station is in good condition for a long time.

IV. Summary

The inspection and maintenance of internal components of the welding station are crucial to ensure stable and efficient operation. By regularly inspecting important components such as heating elements, temperature sensors, control circuits, and power cords, and performing maintenance measures such as cleaning, lubrication, replacement of aging components, and calibration, the service life of the welding station can be effectively extended, and the welding quality and work efficiency can be improved. Operators should strictly follow operating specifications and safety precautions, establish regular maintenance plans, and ensure that the welding station is always in optimal working condition.