SK-YJ000HWXCHT-KP 100004

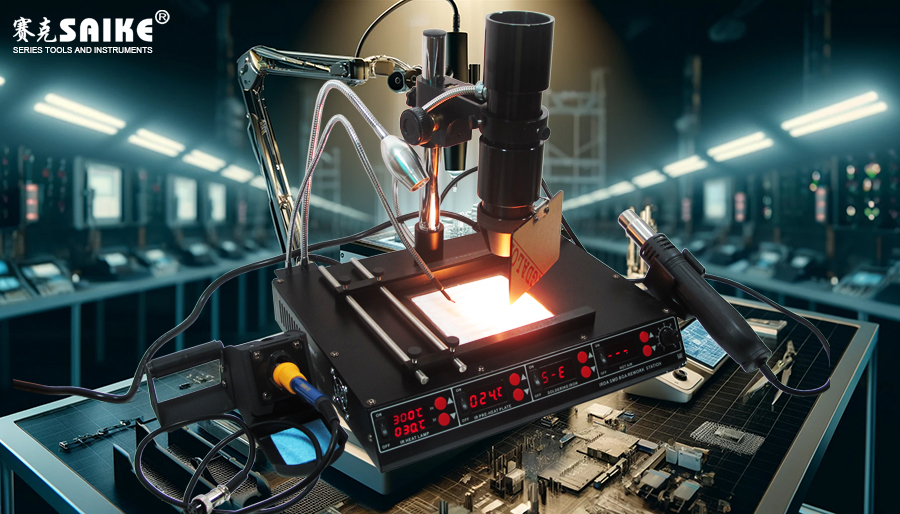

An infrared desoldering station is a crucial equipment used for soldering and desoldering high-density and precision components in electronic repair and manufacturing. It ensures that sensitive electronic components are not damaged by precisely controlling infrared radiation to uniformly heat the target area. This article will introduce the main components of the infrared desoldering station in detail, including the infrared emitter, control system, and other key parts.

I. Infrared Emitter

1.Infrared Lamp:

– The core component of the infrared desoldering station is the infrared lamp, which is usually a halogen lamp or a ceramic lamp capable of emitting infrared radiation.

– These lamps usually have adjustable power output to adapt to different heating needs.

2.Emitter Optical System:

– The infrared emitter optical system is used to focus and guide infrared radiation, ensuring that heat is concentrated on the target solder joint or component.

– By adjusting the lens or reflector, the optical system can precisely locate the target area.

II. Temperature Control System

1.Temperature Sensor:

– Infrared desoldering stations are usually equipped with infrared or thermocouple temperature sensors for real-time monitoring of the temperature of solder joints or components.

– These sensors feed data back to the control system for precise temperature control.

2.PID Controller:

– The PID (Proportional-Integral-Derivative) controller is the core of temperature control. It receives data from the temperature sensor and adjusts the power output of the infrared emitter through an algorithm to maintain stable temperature.

3.Programmable Logic Controller (PLC):

– Advanced infrared desoldering stations are equipped with a PLC, which can preset and store temperature curves, automatically executing complex soldering and desoldering processes.

III. User Interface and Operating System

1.Touch Screen or Control Panel:

– Infrared desoldering stations usually have an intuitive touch screen or control panel through which users can set parameters such as temperature, time, and power.

– The user interface typically displays real-time temperature and operating status, facilitating operator monitoring and adjustment.

2.Software and Firmware:

– The software and firmware of the control system ensure that the equipment can execute precise heating programs and allow users to monitor and record data through software.

IV. Mechanical Structure and Other Components

1.Workbench and Fixture:

– The infrared desoldering station is equipped with a stable workbench and adjustable fixtures to fix the circuit board or components, ensuring accurate positioning during the heating process.

– The workbench material is usually high-temperature resistant and designed with conductive or anti-static properties.

2.Cooling and Exhaust System:

– Some infrared desoldering stations are equipped with fans or external exhaust systems to cool the equipment and exhaust smoke and gases generated during the heating process.

3.Safety Protection Device:

– Including overheat protection, power-off protection, and door lock devices, etc., to ensure that the equipment can automatically stop heating in case of failure, protecting the safety of operators and equipment.

V. Conclusion

The main components of the infrared desoldering station work together to ensure stable heating and precise temperature control in the high-precision electronic repair and manufacturing process. The infrared emitter concentrates thermal energy on the target area through the optical system, while the temperature control system ensures the stability and precision of the heating process. The user interface and operating system provide an intuitive operating experience, while the mechanical structure and other auxiliary components ensure safe and efficient operation. Mastering the functions and working principles of these key components helps better utilize the infrared desoldering station and improve the quality and efficiency of electronic repairs.