SK-YJ000RFSHY-KP 100001

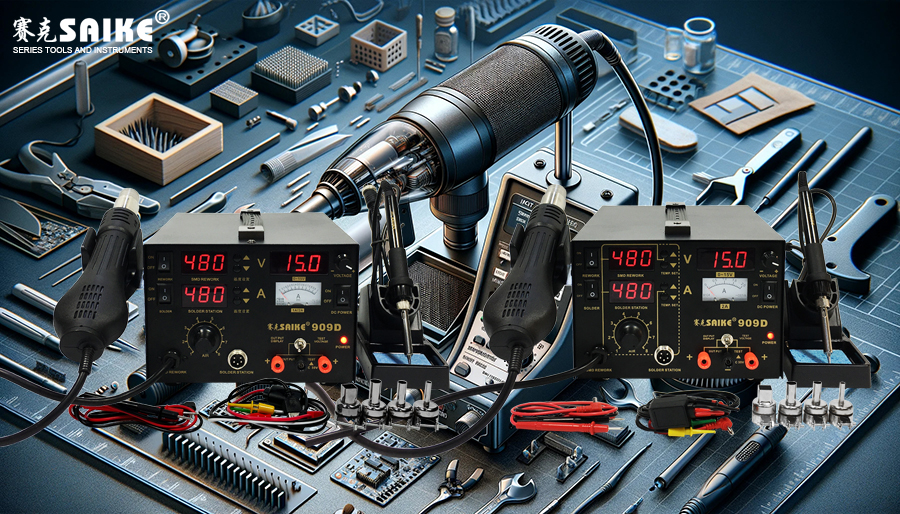

The hot air rework station is a commonly used electronic repair tool, primarily for soldering and desoldering electronic components. Its components include the nozzle, heater, control panel, etc. The following is a detailed introduction to these key parts and their functions.

I. Nozzle

The nozzle is a crucial part of the hot air rework station, guiding hot air to the components that need to be desoldered.

1.Material and Shape

– Nozzles are typically made of high-temperature resistant metal or ceramic materials to ensure they don’t deform or damage under high temperatures.

– Different shaped nozzles are suitable for different desoldering tasks. For instance, a circular nozzle is ideal for focused heating, while a flat nozzle is better for heating larger areas.

2.Replacement and Installation

– Nozzles are often replaceable, allowing users to switch between different types based on specific needs.

– When installing the nozzle, it’s essential to ensure it’s securely fixed to prevent it from falling off during use.

II. Heater

The heater is the core component of the hot air rework station, responsible for heating the air and delivering it to the work area through the nozzle.

1.Heating Element

– The heater commonly uses ceramic heating elements or metal heating wires, which can quickly heat up and maintain a stable temperature.

– These heating elements have a long lifespan and provide uniform heat output.

2.Temperature Control

– The heater temperature can be adjusted through the control panel, typically ranging from 100°C to 500°C.

– Precise temperature control is crucial to avoid damaging components and solder pads.

III. Control Panel

The control panel is the operational center of the hot air rework station, used to set and monitor various work parameters.

1.Temperature Control

– The control panel features a temperature adjustment knob or digital display, allowing users to easily set the desired working temperature.

– High-end models might have PID temperature control for precise temperature maintenance.

2.Air Speed Adjustment

– The control panel also includes air speed adjustment, allowing users to adjust the hot air flow based on the desoldering task.

– Appropriate air speed improves desoldering efficiency while preventing strong air currents from damaging components.

3.Operational Modes

– Some hot air rework stations offer multiple operational modes, such as continuous heating and pulsed heating, to suit different soldering and desoldering needs.

– Advanced models might have a memory function to save commonly used temperature and air speed settings.

IV. Other Auxiliary Components

In addition to the main components, the hot air rework station includes auxiliary parts that enhance efficiency and operational safety.

1.Stand and Support

– Hot air rework stations often come with a stand or support to hold the hot air gun when not in use, facilitating easy access for operators.

– These stands are designed to be heat-resistant and anti-slip for safety.

2.Filtration System

– Some hot air rework stations have a built-in filtration system to remove dust and impurities from the air, ensuring the heater’s longevity and stability.

– High-end models might include an activated carbon filter for enhanced air purity.

V. Conclusion

The hot air rework station consists of several key components, including the nozzle, heater, and control panel, each playing a vital role in the system. The nozzle directs the hot air, the heater provides the heat source, and the control panel regulates and monitors various parameters, ensuring a smooth desoldering process. Understanding these components’ functions and characteristics enables users to better utilize the hot air rework station, improving the efficiency and quality of electronic repair work.