SK-YJ000RFSHY-KP 100010

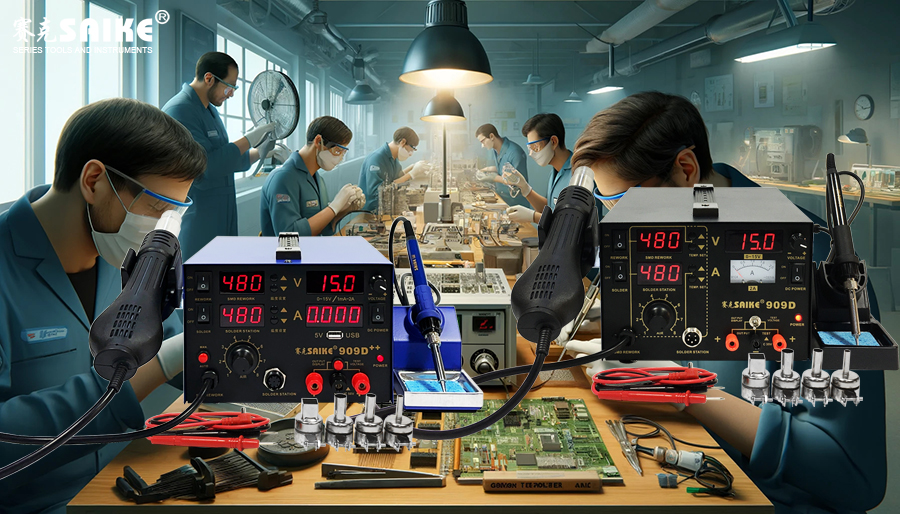

The hot air rework station is a commonly used tool in electronic maintenance and manufacturing processes, widely applied in component desoldering, SMD installation, and circuit board repairs. This article will introduce the common operating steps and precautions for the hot air rework station, helping users better master the use of this tool.

I. Common Operating Steps for Hot Air Rework Station

1.Preparation

– Equipment Inspection: Before using the hot air rework station, check if the equipment is intact, including power cords, hot air guns, control panels, and other components.

– Temperature and Airflow Setting: Set the appropriate temperature and airflow based on the type of component to be desoldered and the material of the circuit board. Generally, the temperature for desoldering components is set between 300℃ and 350℃, with the airflow adjusted according to specific needs.

– Safety Protection: Wear an anti-static bracelet to ensure a static-free work environment, and prepare protective glasses to prevent molten solder from splashing into the eyes during the soldering process.

2.Desoldering Operation

– Preheating Components: Aim the hot air gun at the component to be desoldered, maintain a proper distance (about 2-3 centimeters), and heat evenly. Avoid concentrated heating on one spot to prevent damage to the component or circuit board.

– Melting Solder: Once the solder melts, gently remove the component with tweezers. Be cautious and avoid excessive force that may cause the solder pad to fall off or damage the circuit board.

– Cleaning Solder Pads: Use a solder sucker or solder wick to clean residual solder on the solder pad, ensuring a flat surface for subsequent soldering of new components.

3.Installing New Components

– Applying Flux: Apply a moderate amount of flux on the solder pad to facilitate the flow and adhesion of solder.

– Soldering Components: Place the new component on the solder pad, heat it with a hot air gun until the solder melts and securely connects the component and the solder pad.

– Inspecting Solder Joints: After soldering, check if the solder joints are solid and the solder is evenly distributed, ensuring there is no cold solder joint or false soldering.

II. Precautions for Hot Air Rework Station

1.Temperature Control

– Avoid Excessive Temperature: High temperatures can damage components and circuit boards, so set the temperature reasonably based on the heat resistance of the components.

– Gradual Heating: It is recommended to gradually increase the temperature during desoldering to prevent one-time high temperatures from damaging components.

2.Airflow Adjustment

– Appropriate Airflow: Excessive airflow can blow away small components, while insufficient airflow reduces heating efficiency. Adjust the airflow based on the size and type of components.

– Even Heating: Keep the hot air gun moving evenly to avoid local overheating and ensure uniform heating of components.

3.Safe Operation

– Anti-static Measures: Electronic components are sensitive to static electricity. Wear an anti-static bracelet during operation, and the work surface should also be covered with an anti-static pad.

– Protective Measures: Wear protective glasses during operation to prevent high-temperature solder from splashing into the eyes and causing injury.

– Ventilated Environment: Ensure good ventilation in the work environment to avoid long-term inhalation of solder fumes, which can be harmful to health.

4.Equipment Maintenance

– Regular Equipment Inspection: Regularly check various parts of the hot air rework station to ensure normal operation. Promptly repair or replace any issues found.

– Cleaning and Maintenance: Clean the equipment after use, especially the nozzle of the hot air gun, to avoid solder residue affecting subsequent use.

III. Summary

The hot air rework station is a crucial tool in electronic maintenance and production. Following correct operating steps and precautions can effectively improve work efficiency and reduce damage to components and circuit boards. By reasonably setting the temperature and airflow, focusing on safety protection and equipment maintenance, smooth desoldering work can be ensured. Hopefully, this article will help readers better master the use of the hot air rework station and achieve efficient and safe electronic maintenance operations.