SK-YJ000ZLWYDY-KP 100033

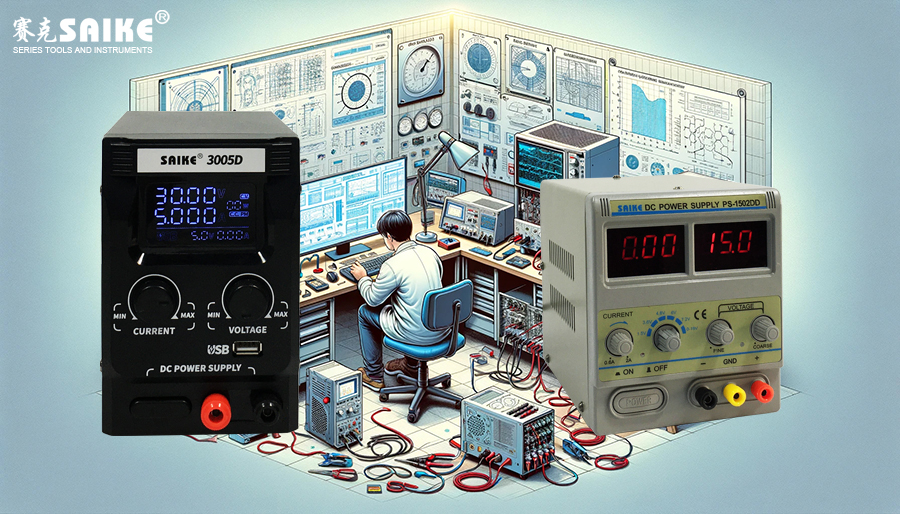

The DC Stabilized Power Supply is an indispensable tool in electronic experiments and circuit testing. It is mainly used to provide stable output voltage and current to meet the power requirements of different devices. To ensure its reliable performance, thorough testing and debugging of the DC Stabilized Power Supply are very necessary. This article will introduce the testing and debugging process of the DC Stabilized Power Supply in detail.

I. Preparation before Testing

1.Check the basic parameters of the power supply:

– Confirm that the input voltage and frequency of the power supply meet the specifications.

– Check whether the range of output voltage and current is suitable for the test equipment.

2.Prepare test equipment:

– Use an electronic load to simulate different current consumption.

– Prepare a digital multimeter or oscilloscope to measure the stability and accuracy of the output voltage.

3.Check the physical condition of the power supply:

– Check whether the power interface and cables are damaged or loose.

– Ensure that the cooling system is working properly to avoid overheating.

II. Performance Test Steps

1.Accuracy test of output voltage and current:

– Adjust the output voltage of the power supply to the lowest, gradually increase it to the highest, and monitor the voltage value with a digital multimeter at the same time.

– Check whether the power supply can output accurate current according to the setting, especially under different load conditions.

2.Linearity and load regulation test:

– Check the stability of the output voltage by changing the load current.

– Record the linear adjustment ability of the power supply under different loads, and observe the changes in voltage and current.

3.Ripple and noise test:

– Use an oscilloscope to check the ripple and noise level of the output voltage.

– Analyze whether it exceeds the specified ripple and noise limits.

III. Troubleshooting and Debugging

1.Detect the protection function of the power supply:

– Test whether the overload protection, short circuit protection, and temperature protection are working properly.

– Check the response of the power supply by intentionally short-circuiting or overloading.

2.Adjust internal settings:

– If necessary, adjust the potentiometer inside the power supply to optimize output stability.

– Check and calibrate the current detection circuit and voltage feedback loop.

3.Software and interface detection:

– If the power supply has a digital control interface, check related software and firmware updates.

– Test the responsiveness and accuracy of the control software.

IV. Maintenance and Long-term Stability Evaluation

1.Regular maintenance suggestions:

– Regularly clean the inside of the power supply and fans to prevent dust accumulation from affecting performance.

– Check whether the power adapter and power cord need to be replaced.

2.Long-term stability test:

– Conduct long-term operation tests to evaluate the performance of the power supply under continuous working conditions.

– Record any performance degradation or failure modes to provide a basis for future maintenance.

V. Summary

Through the above testing and debugging steps, the performance of the DC Stabilized Power Supply can be effectively ensured to meet design standards and usage requirements. Reasonable maintenance and regular performance testing can not only extend the service life of the power supply but also ensure equipment safety and efficiency in daily use. Each test and debugging is a verification of the reliability of the power supply and a commitment to user safety.