SK-YJ000DDXXQ-KP 100006

The electric solder sucker is an indispensable tool in the field of electronic manufacturing and repair, especially when removing and replacing circuit board components. Effective configuration and optimization of the electric solder sucker can not only improve work efficiency but also ensure welding quality and long-term stability of the equipment. Here are some key configuration optimization tips to help users maximize the performance of their electric solder suckers.

I. Choosing the Right Nozzle

1.Matching Nozzle Size: When selecting a nozzle, ensure its size matches the size of the solder joint being sucked. An oversized nozzle may damage adjacent components, while an undersized nozzle may result in insufficient suction.

2.Material Selection: High-quality stainless steel or nickel alloy nozzles provide better heat resistance and corrosion resistance, thereby extending service life.

II. Adjusting Suction and Temperature Settings

1.Suction Adjustment: The suction of the electric solder sucker needs to be adjusted according to the size of the solder joint and the nature of the solder. For larger solder joints or those containing more solder, increase the suction.

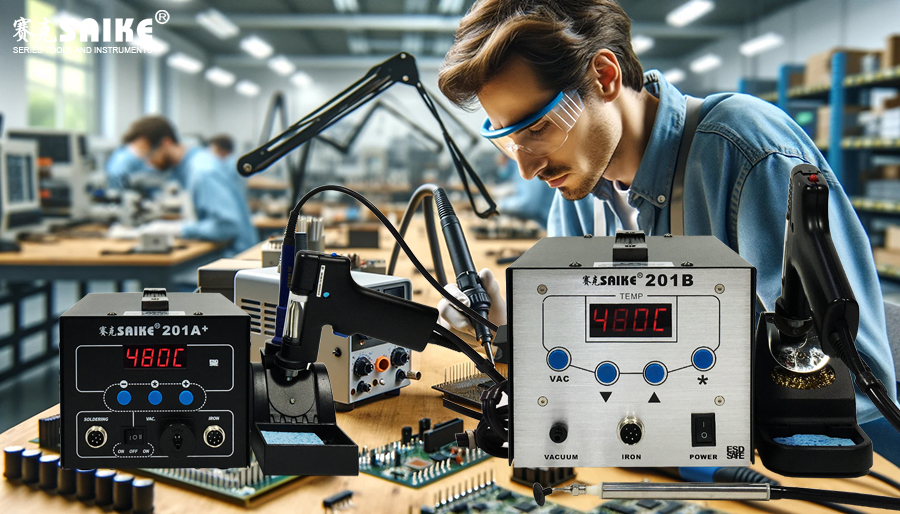

2.Temperature Control: The temperature should be set according to the melting point of the solder. While using a higher temperature can quickly melt the solder, it may also damage the circuit board or components. It is recommended to use a solder sucker with adjustable temperature mode.

III. Regular Maintenance and Cleaning

1.Cleaning the Nozzle: Regularly clean residual solder inside the nozzle to prevent blockage and maintain good suction. Use a dedicated cleaning needle or copper wire brush for cleaning.

2.Checking Seals and Filters: Ensure that the solder sucker’s seals are intact and the filters are clean and unobstructed, which is crucial for maintaining optimal suction.

IV. Adopting High-Quality Accessories and Replacement Parts

1.Preferred Accessories: Using official or certified replacement parts and accessories can reduce the risk of equipment failure and ensure the reliability of equipment operation.

2.Backup Nozzles and Filters: Keep a certain number of backup nozzles and filters to facilitate quick replacement when needed without affecting work progress.

V. Implementing Correct Operating Techniques

1.Preheating Time: Before starting to suck solder, allow the solder sucker to fully preheat to the set temperature to ensure that the solder can be quickly and completely sucked away.

2.Operating Method: When sucking solder, gently touch the solder joint and quickly lift the solder sucker vertically to avoid excessive force on the solder pad, which may cause damage.

VI. Summary

By following these configuration optimization tips, the performance and efficiency of the electric solder sucker can be effectively improved while protecting the equipment and the circuit board being processed. These measures can help professionals and enthusiasts achieve more precise and high-quality welding effects, ensuring the smooth progress of electronic equipment maintenance and manufacturing work.