SK-YJ000DDXXQ-KP 100025

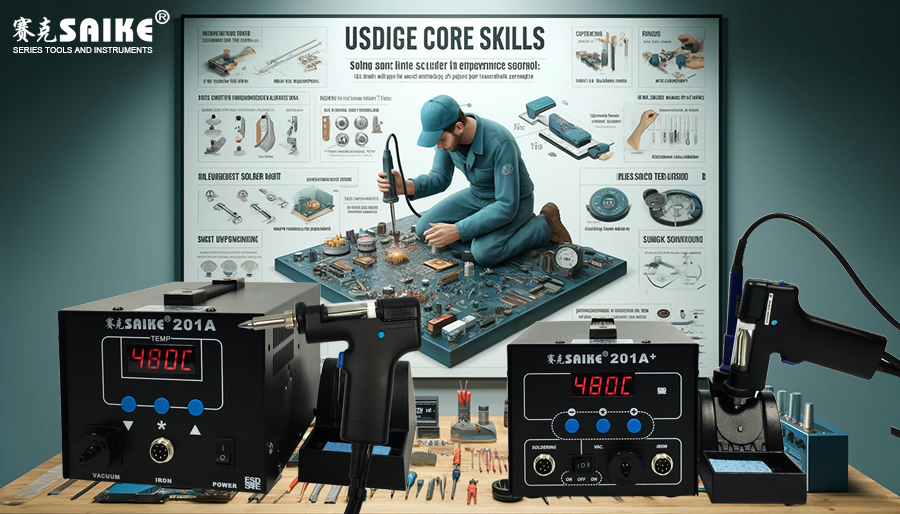

The electric solder sucker is an important tool in electronic soldering and maintenance work, and its correct and efficient use has a significant impact on improving work quality and efficiency. The following is a review and summary of the key skill points for using an electric solder sucker, designed to help operators master core operating skills and ensure optimal soldering results.

I. Proper Equipment Setup

1.Temperature Control

– Adjust the electric solder sucker to the appropriate temperature, usually between 350°C and 400°C, depending on the type of solder and the sensitivity of the components.

– Ensure that the equipment reaches the set temperature before use to guarantee rapid solder melting and effective suction.

2.Selection and Maintenance of Soldering Tips

– Choose the appropriate soldering tip based on the size and density of the solder joints. Use a fine tip for small solder joints and a wider tip for larger areas of solder.

– Regularly clean the soldering tip to remove accumulated solder residue and oxides, maintaining good thermal conductivity.

II. Operating Skills

1.Precise Solder Joint Positioning

– Before using the solder sucker, accurately locate the solder joints to ensure that the soldering tip completely covers the joint, optimizing heat transfer and solder suction effectiveness.

– Stabilize your hand to avoid movement during heating or solder suction, preventing damage to the solder joint or incomplete solder suction.

2.Fast and Effective Solder Suction Operation

– Activate the solder suction pump immediately after the solder melts, quickly and efficiently sucking away the molten solder in one go to avoid repeated heating and reduce thermal damage to the circuit board and components.

– Optimize solder suction time by controlling the duration of each suction to avoid overheating.

III. Maintenance and Care

1.Regular Inspection

– Regularly inspect the power cord and solder suction pump of the solder sucker to ensure there are no issues with wear or clogging.

– Check if the soldering tip needs to be replaced to ensure solder suction efficiency and safety.

2.Cleaning and Maintenance

– After use, clean the soldering tip and solder suction port, using specialized tools or a wet sponge to remove residual solder and oxides.

– When storing, place the electric solder sucker in a dry and clean environment to avoid dust and moisture erosion.

IV. Summary

Effective use of the electric solder sucker requires not only a deep understanding of the equipment but also precise operation skills and good maintenance habits. By practicing these key skill points, the quality and efficiency of soldering operations can be greatly improved, while also extending the lifespan of the equipment. Continuous learning and practice are key to success for any electronic maintenance technician.