SK-YJ000DDXXQ-KP 100009

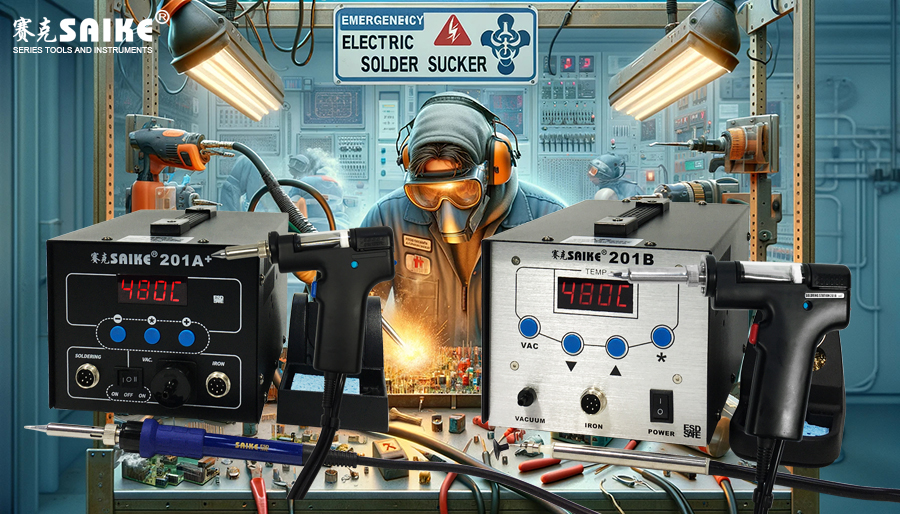

I. Overview of Electric Solder Sucker Gun Safety

Electric solder sucker guns are commonly used tools in electronic manufacturing and repair, designed to quickly and effectively remove solder from soldering joints. While these tools are highly practical, improper use or equipment failure can lead to burns, electric shocks, or other accidents. Understanding and implementing emergency measures are crucial to ensure user safety.

II. Preventive Measures

1.Pre-use Inspection

– Ensure that the wires and plugs of the solder sucker gun are not worn or damaged.

– Check the heating element of the solder sucker gun for integrity, ensuring there are no loose or damaged parts.

2.Proper Operation

– When using the solder sucker gun, be sure to wear protective glasses and heat-resistant gloves.

– Avoid pointing the solder sucker gun at yourself or others.

– Ensure good ventilation in the work area to avoid inhaling harmful fumes.

3.Maintenance and Storage

– Regularly clean the solder sucker nozzle to prevent clogging and overheating.

– After use, place the solder sucker gun on fireproof material to cool down.

– When storing the solder sucker gun, ensure it is kept away from flammable materials and damp environments.

III. Responding to Emergencies

1.Burn Treatment

– Immediately stop using the equipment and cut off the power.

– For minor burns, cool the burned area with cold water for at least 10 minutes.

– Avoid using ice for direct cold compress to prevent more severe injury.

– After a minor burn, apply a sterile burn ointment and cover with a sterile gauze.

– For severe burns, seek professional medical help immediately.

2.Electric Shock Accident Handling

– Disconnect the power immediately.

– Do not touch the person who has been electrocuted until the scene is confirmed to be safe.

– If the injured person is unconscious or shows obvious physical abnormalities, immediately call an emergency number for medical assistance.

3.Equipment Malfunction

– Once abnormal heating or smoke generation is detected in the solder sucker gun, it should be immediately shut down and disconnected.

– Do not attempt to disassemble or repair the damaged solder sucker gun yourself. It should be sent to professionals for inspection and maintenance.

IV. Summary

Although electric solder sucker guns are powerful tools for electronic work, they must be used cautiously to avoid accidents. Implementing the aforementioned preventive measures and emergency response measures can significantly reduce the risks during operation and ensure user safety. Remaining vigilant and following safe operating procedures is key to avoiding accidents in any work.