SK-YJ000HWXCHT-KP 100005

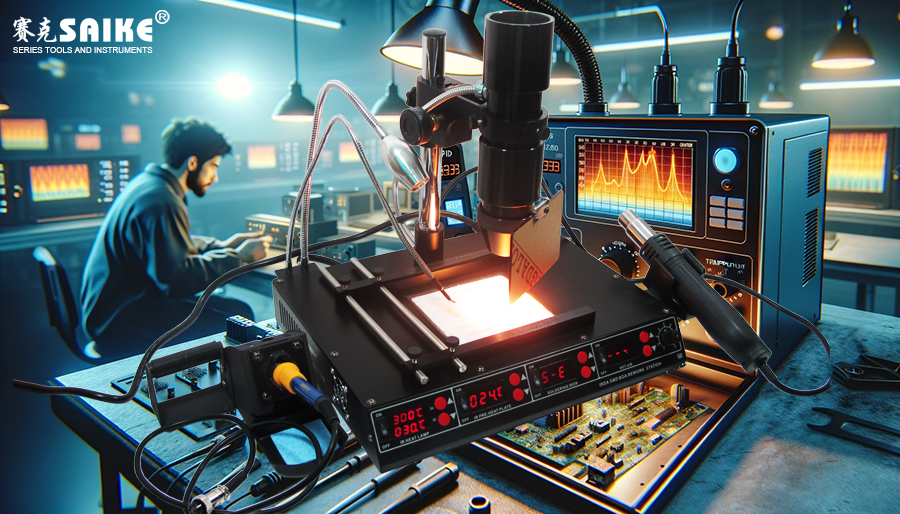

Infrared rework stations achieve efficient desoldering of electronic components through precise temperature control and monitoring techniques. This technology is particularly important when handling sensitive and delicate electronic components, as overheating or uneven heating can damage circuit boards and components. This article explores the temperature control and monitoring techniques of infrared rework stations, delving into precise control and adjustment skills.

I. Temperature Control Technology

1.PID Temperature Controller:

– Working Principle: The PID (Proportional-Integral-Derivative) controller adjusts the output power of the infrared emitter based on data from the temperature sensor, ensuring that the actual temperature remains close to the set value.

– Adjustment Method: By adjusting the proportional, integral, and derivative coefficients, the heating response time and stability can be optimized.

– Advantages: High temperature control precision, which can reduce temperature fluctuations and thermal shock.

2.Programmable Temperature Profiles:

– Preset Profiles: Advanced infrared rework stations can preset different temperature profiles, automatically adjusting the temperature rise and fall speeds to meet the requirements of different solders or components.

– Custom Modes: Users can create customized temperature profiles based on actual needs to adapt to special materials and processes.

3.Multi-zone Temperature Control:

– Principle: Utilizing multiple infrared emitters and sensors to independently control the temperature of different soldering points in various zones.

– Advantages: Suitable for complex multilayer circuit boards, ensuring uniform heating and reducing hot and cold spots.

II. Temperature Monitoring Technology

1.Infrared Sensors:

– Principle: Infrared sensors estimate the temperature of the target soldering point by detecting its infrared radiation intensity. The data is then fed back to the control system in real-time.

– Advantages: Non-contact measurement, suitable for temperature monitoring of sensitive components.

2.Thermocouple Sensors:

– Principle: Thermocouples convert temperature differences into electrical signals to measure the target temperature.

– Advantages: Fast response and suitable for high-precision temperature monitoring.

3.Thermal Imaging Monitoring:

– Principle: Thermal imagers provide a temperature distribution image of the entire working area through infrared imaging technology.

– Advantages: Intuitively displays the temperature distribution of the entire heating area, facilitating temperature adjustment and correction.

III. Precise Control and Adjustment Skills

1.Initial Temperature Setting:

– Set the initial temperature based on the thermal sensitivity of the target components and circuit boards.

– Ensure that the temperature does not exceed the thermal threshold of the components but is sufficient to melt the solder.

2.Adjusting the Heating Rate:

– Adjust the heating rate to meet the target temperature profile, avoiding damage to the components caused by too rapid or too slow heating.

– For sensitive components, gradual heating should be applied to avoid thermal shock.

3.Real-time Temperature Monitoring and Feedback:

– Use infrared sensors or thermocouples for real-time monitoring and feed the data back to the control system.

– If the temperature deviation is large, adjust the heating power in a timely manner to achieve the desired target.

4.Regular Sensor Calibration:

– Regularly calibrate the temperature sensor to ensure data accuracy.

– If the sensor is damaged or drifts, it should be replaced promptly.

IV. Summary

The temperature control and monitoring techniques of infrared rework stations are crucial factors in ensuring precise desoldering and soldering. Technologies such as PID controllers, preset temperature profiles, and multi-zone controls make temperature control more stable and precise. Monitoring tools like infrared sensors, thermocouples, and thermal imagers ensure real-time understanding of the heating process, providing feedback for operations. Through reasonable initial settings, heating rate adjustments, and real-time monitoring skills, technicians can ensure that infrared rework stations achieve optimal results in complex and precision electronic repairs.