SK-YJ000HWXCHT-KP 100001

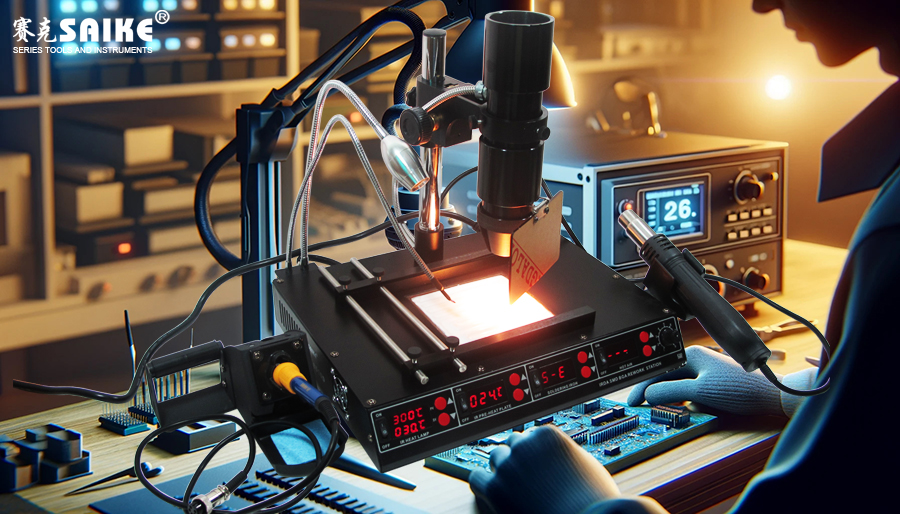

In the modern electronic repair industry, the infrared rework station has become an essential tool for repairing and reworking delicate electronic components, thanks to its precise soldering and desoldering capabilities. It can quickly and evenly heat solder joints without damaging surrounding electronic components. This article will detail the definition, working principle, and the significance of the infrared rework station in electronic repairs.

I. Definition of Infrared Rework Station

An infrared rework station is a device that utilizes infrared radiation technology to heat solder joints or electronic components on a circuit board, enabling precise soldering and desoldering. It is suitable for non-destructive desoldering and re-soldering of high-density packaged components (such as BGA, QFP, etc.), especially for multilayer circuit boards and sensitive components.

II. Working Principle of the Infrared Rework Station

1.Infrared Radiation Heating:

– The infrared rework station emits infrared radiation using infrared lamps or heating elements.

– The infrared radiation is absorbed by the circuit board and solder joints, converting the radiated energy directly into heat.

2.Uniform Heating:

– Through precise control of the infrared beam, heat can be concentrated in the target area, providing uniform and rapid heating while preventing damage to surrounding sensitive components.

3.Temperature Control and Sensing:

– The infrared rework station is equipped with temperature sensors and a feedback system to monitor and adjust the actual temperature of the solder joints, ensuring that the soldering process follows the required temperature profile.

4.Automatic or Manual Operation:

– Advanced equipment can automatically execute preset soldering or desoldering programs, or it can be manually adjusted to meet specific soldering needs.

III. The Importance of Infrared Rework Station in Electronic Repair

1.Precise Soldering and Desoldering:

– For high-density packaged electronic components such as BGA, QFN, and CSP, the infrared rework station can concentrate heat on solder joints without damaging surrounding circuit boards and components, achieving precise soldering and desoldering.

2.Reduced Thermal Stress:

– Uniform heating from infrared radiation reduces thermal stress generated during the heating process of the circuit board and components, preventing solder joint cracking and circuit board warping.

3.Adaptation to Multilayer Circuit Boards:

– Multilayer circuit boards have different thermal conductivity characteristics at different layers. The infrared rework station ensures lossless soldering by precisely controlling the heating speed and temperature.

4.Time and Cost Savings:

– Automated and programmable infrared rework stations can improve repair efficiency, reduce rework time and material waste, and effectively reduce repair costs.

5.Improved Production Quality:

– In electronic repairs and reworks, the infrared rework station ensures consistent and reliable soldering quality by accurately controlling the temperature profile, improving the quality of the finished product.

IV. Conclusion

As an essential tool in modern electronic repairs, the infrared rework station exhibits unique advantages in soldering and desoldering high-density and finely packaged electronic components due to its precise and uniform heating capability. Understanding the definition and working principle of the infrared rework station allows for better utilization of its potential in electronic repairs, effectively reducing repair risks and ensuring high-quality repair results.