SK-YJ000YRT-KP 100008

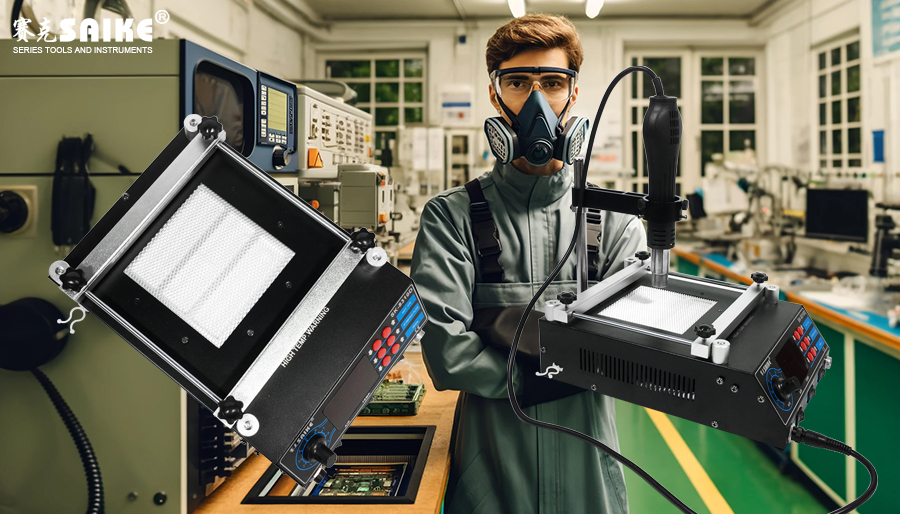

In the electronics manufacturing and repair industry, using a preheating station to heat circuit boards is a common practice. Operating a preheating station involves exposure to high temperatures and potential chemical exposures, so the correct use of Personal Protective Equipment (PPE) is crucial to ensuring the safety of operators. This article will detail the PPE that should be worn when using a preheating station, as well as the importance and selection criteria of this equipment.

I. Essential PPE for Preheating Station Operations

1.Heat-resistant gloves

– Purpose: To protect the operator’s hands from direct heat injury during preheating station operations.

– Selection criteria: Choose gloves that can withstand high temperatures and have good heat insulation properties. Recommended materials include silicone, leather, or specially treated fabrics.

2.Protective glasses

– Purpose: To protect the eyes from hot air, dust, and possible chemical splashes.

– Selection criteria: Select protective glasses that meet safety standards, ensuring that they fully cover the eye area and prevent any microscopic particles from entering.

3.Protective masks or respirators

– Purpose: Using a preheating station may release harmful gases or fumes, especially when heating chemically treated materials.

– Selection criteria: Choose an appropriate protective mask based on the specific needs of the work environment. For large amounts of chemical fumes, a respirator with an organic vapor filter should be used.

4.Anti-static clothing

– Purpose: To prevent electrostatic accumulation when handling sensitive electronic equipment, thereby protecting electronic components from electrostatic damage.

– Selection criteria: Clothing should meet ESD (ElectroStatic Discharge) protection standards and typically includes anti-static work clothes and shoes.

II. Importance of PPE

1.Avoiding thermal injury: The high temperatures generated by the preheating station during operation can easily cause burns. Appropriate protective gloves and clothing can effectively isolate high temperatures and protect the operator from harm.

2.Preventing eye injury: Protective glasses can prevent hot air and splashing chemicals from directly contacting the eyes, avoiding serious eye damage.

3.Preventing respiratory damage: Some circuit boards may release harmful chemicals when heated, and appropriate respiratory protection can prevent the inhalation of harmful gases or dust.

4.Reducing electrostatic damage: In the manufacturing and repair of electronic equipment, static electricity can cause serious component damage, and anti-static clothing is an important means of preventing such problems.

III. Correct Use and Maintenance of PPE

1.Correct wearing: Ensure that all PPE is worn properly before entering the work area, and check that the equipment is intact.

2.Regular inspection and replacement: Regularly inspect the integrity and functionality of all PPE, and promptly replace worn or damaged equipment.

3.Cleaning and storage: Clean and store PPE according to the manufacturer’s guidelines after use, ensuring that the equipment remains clean, dry, and in good working condition.

IV. Conclusion

When using a preheating station, correct PPE is a basic requirement to ensure operational safety. By selecting appropriate protective equipment and using and maintaining it correctly, the safety risks in the workplace can be significantly reduced, protecting the health of operators while ensuring efficient and quality production and maintenance work. Investing in PPE is an important investment in work safety, which has long-term significance for improving the safety standards and quality control of the entire work environment.