SK-YJ000RFSHY-KP 100050

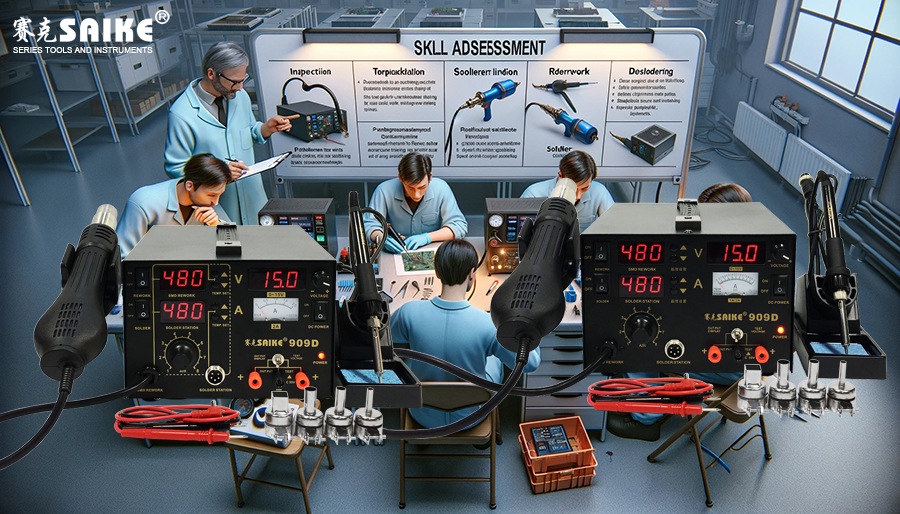

In the field of modern electronics manufacturing and maintenance, mastering the use of hot air rework station power supply equipment is an essential skill. To continuously improve and innovate in this field, further study and research on advanced desoldering techniques and high-precision circuit repairs are crucial. This article explores the learning content, research methods, and applications of these directions.

I. Advanced Desoldering Techniques

1.Hot Air Desoldering

– Desoldering of Different Components: Studying how to desolder various types of components such as QFP, BGA, CSP, etc., and mastering the optimal temperature and airflow settings for each component.

– Selection of Solder Alloys: Learning about different types of solder alloys and their characteristics, selecting suitable solder alloys to optimize desoldering effects.

– Hot Air Gun Operation Skills: Mastering the movement and angle of the hot air gun to ensure uniform heating and avoid damage to components and circuit boards.

2.Laser Desoldering Technique

– Laser Parameter Settings: Learning how to adjust laser power, pulse width, and frequency to suit different soldering materials and components.

– Laser Path Planning: Studying the laser’s movement path on the circuit board to ensure precise desoldering and avoid thermal damage.

– Combination of Laser and Traditional Methods: Exploring the combined use of laser technology and hot air desoldering techniques to enhance desoldering efficiency and precision.

II. High-Precision Circuit Repair

1.Precision Soldering Techniques

– Micro-soldering Technique: Learning to solder on tiny solder joints, ensuring strong and conductive solder joints.

– Optimization of Soldering Equipment: Utilizing advanced soldering equipment such as micro soldering irons and precision soldering stations to enhance soldering accuracy.

– Selection of Soldering Materials: Choosing suitable solder and flux to improve soldering quality.

2.Use of High-Resolution Microscopes

– Microscope Inspection Techniques: Learning to use microscopes for detailed circuit board inspections, identifying minuscule soldering defects and circuit failures.

– Microscope-Assisted Soldering: Performing soldering operations under a microscope to enhance soldering precision and quality.

3.Accurate Electrical Testing

– Multi-function Test Instruments: Learning to use multi-function test instruments such as oscilloscopes, multimeters, and logic analyzers for comprehensive electrical testing.

– Automated Test Systems: Studying the use of Automated Test Equipment (ATE) to improve testing efficiency and accuracy.

– Fault Diagnosis Techniques: Mastering fault diagnosis techniques to quickly locate and repair fault points on the circuit board.

III. Research Methods and Applications

1.Combination of Theoretical Learning and Practical Application

– Professional Books and Literature: Reading professional books and literature to understand the latest desoldering techniques and circuit repair methods.

– Laboratory Practice: Conducting extensive practical operations in the laboratory to validate theoretical knowledge and enhance operational skills.

2.Technical Communication and Training

– Technical Seminars: Attending industry technical seminars, communicating and learning from experts, and staying updated on the latest technological developments.

– Training Courses: Participating in professional training courses to systematically learn advanced desoldering techniques and high-precision circuit repairs.

3.Innovation and Research and Development

– New Equipment Development: Participating in the development of new desoldering equipment and test instruments to explore more efficient and precise operational methods.

– Process Improvement: Researching and improving existing processes to enhance the reliability and consistency of operations.

IV. Summary

Further studying and researching the advanced desoldering technology and high-precision circuit maintenance of the three-in-one hot air desoldering station power supply equipment is crucial for electronics manufacturing and maintenance practitioners. By deeply studying hot air desoldering and laser soldering technology, mastering precision soldering, high-resolution microscopy, and other high-precision circuit maintenance skills, combining theoretical learning with practical operations, actively participating in technical exchanges and training, and continuously innovating and researching, professionals can effectively enhance their professional abilities and promote personal and industry development.