SK-YJ000HWXCHT-KP 100017

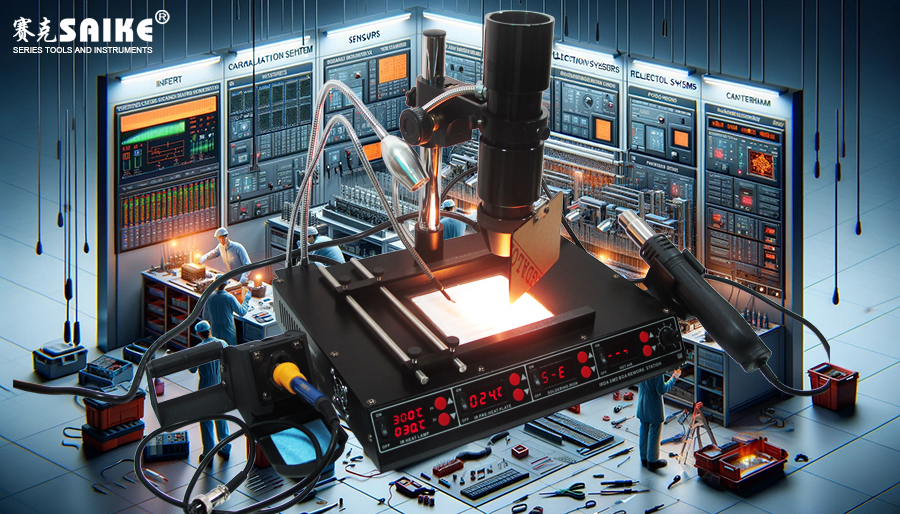

Infrared systems are widely used in electronics manufacturing and repair, heating, temperature control, and other fields, favored for their precise temperature control and efficient heating effects. However, various faults may occur during the operation of infrared systems, affecting operational efficiency and production quality. This article will introduce common fault types and troubleshooting methods for infrared systems, helping users promptly resolve issues and ensure efficient system operation.

I. Common Fault Types of Infrared Systems

1.Unstable or Ineffective Heating:

– The infrared emitter cannot heat normally, resulting in uneven temperature in the target area or failure to reach the set value.

2.Temperature Display Does Not Match Reality:

– The temperature feedback from the temperature sensor does not match the actual temperature in the target area, leading to inaccurate temperature control or system alarms.

3.Control System Malfunction:

– The control panel cannot be operated normally or responds slowly, affecting temperature setting, heating time, and curve control.

4.System Power Off or Failure to Start:

– The system suddenly powers off or cannot be started, resulting in equipment malfunction.

II. Troubleshooting Methods

1.Unstable or Ineffective Heating

– Infrared Emitter Inspection:

– Check the appearance and connection status of the infrared emitter, ensuring no cracks, burns, or loose wiring.

– Test the emitter’s resistance to ensure it falls within the specified resistance range.

– Replace aging or damaged emitters, and ensure new components meet equipment specifications.

– Power Supply and Power Inspection:

– Ensure stable system power connection and test the voltage output of power sockets and plugs for normality.

– Ensure sufficient power supply for the infrared emitter, adjust power output or replace power components.

– Reflection System Cleaning:

– Clean the infrared emitter’s reflection system, including reflectors and lenses, to ensure no dust or oil stains.

2.Temperature Display Does Not Match Reality

– Temperature Sensor Calibration:

– Test the accuracy of the temperature sensor to ensure it feeds back temperature data within a normal range.

– Recalibrate the sensor or replace a malfunctioning one.

– Signal Connection Inspection:

– Check the signal connection between the sensor and the control system, ensuring secure wiring with no breaks or looseness.

– Elimination of Environmental Interference:

– Avoid strong electromagnetic interference and the influence of other heat sources on the sensor signal to ensure stable data transmission.

3.Control System Malfunction

– Control Panel Restart:

– Attempt to shut down and restart the control system to ensure proper initialization.

– Check the buttons, display, and interface of the control panel to ensure proper connection.

– Firmware and Software Updates:

– Update the control system’s firmware and operating software to avoid control system malfunctions caused by software errors.

– If software updates are ineffective, contact the manufacturer for further technical support.

– Circuit Board Inspection:

– Inspect the circuit board and wiring inside the control panel, ensuring no breaks, corrosion, or burn marks.

4.System Power Off or Failure to Start

– Power Cord Inspection:

– Check the power cord and plug for intactness, avoiding breaks or poor contact.

– Test the output voltage of the power socket to ensure it meets the equipment’s voltage requirements.

– Internal Circuit Inspection:

– Inspect the circuit boards and wiring inside the equipment, ensuring all connections are secure with no short circuits or burns.

– Overload Protection Inspection:

– Check the system’s overload protection device to ensure the equipment has not powered off due to power overload or voltage instability.

– After eliminating other faults, reset or replace the overload protection device.

III. Conclusion

Troubleshooting infrared systems requires adopting appropriate inspection and elimination methods for different fault types. By inspecting infrared emitters, temperature sensors, control systems, and power lines, issues such as unstable heating, inaccurate temperature display, control malfunction, or system power-off can be identified and resolved. Meanwhile, regular cleaning, calibration of equipment, software and firmware updates, elimination of signal interference, and electrical troubleshooting can ensure stable operation and extend the service life of the infrared system.