SK-YJ000RFQ-KP 100002

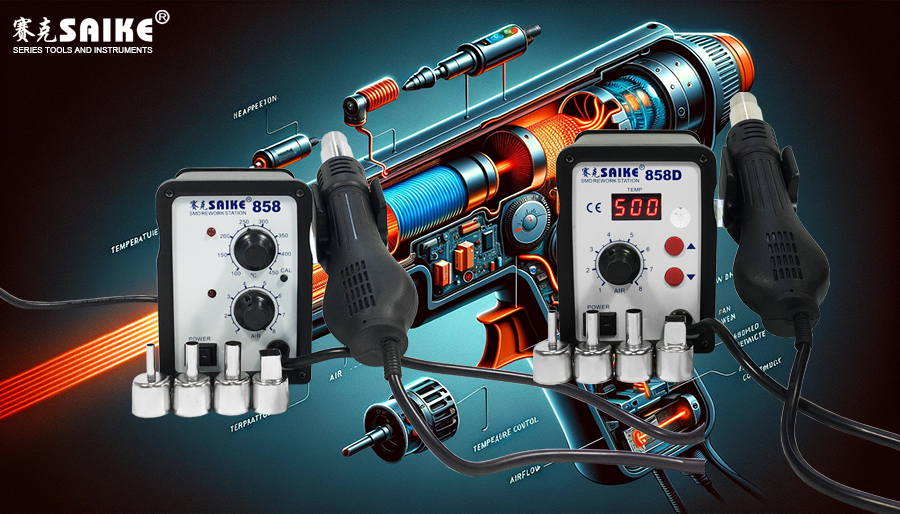

As an efficient and versatile thermal tool, the hot air gun plays a vital role in modern industrial and handicraft fields. Its working principle involves several key components: the heating element, temperature control system, and airflow control. Below, we will delve into the workings of these three core elements.

I. Heating Element

The heating element of the hot air gun is its core component, responsible for converting electrical energy into thermal energy. This element is often made of high-resistance materials, such as nichrome wire, which boasts high resistivity and excellent thermal conductivity. When current passes through the heating element, electrical energy is converted into thermal energy due to resistance, causing the element to rapidly heat up.

In most hot air guns, the heating element is designed in the form of a resistance wire or electric heating element. When the hot air gun is powered on, current flows through the heating element, generating heat and achieving a high-temperature state. This high temperature forms the basis for the hot air gun’s ability to produce hot air.

II. Temperature Control System

The temperature control system is a crucial part of the hot air gun, ensuring stable temperature output during operation and preventing overheating or insufficient temperature.

The temperature control system typically consists of a temperature sensor and a control circuit. The temperature sensor continuously monitors the temperature of the heating element and feeds this information back to the control circuit. The control circuit compares the preset temperature value with the actual monitored temperature and adjusts the current accordingly, controlling the heating rate of the heating element and stabilizing the output temperature within the set range.

Additionally, some advanced hot air guns feature automatic temperature adjustment, which can automatically adjust the temperature based on work requirements, further enhancing work efficiency and safety.

III. Airflow Control

Airflow control is another essential function of the hot air gun, determining the intensity and direction of the hot air blown out.

Inside the hot air gun, there is usually a small fan or blower that sucks in external air and blows it towards the heating element. When the air passes through the high-temperature heating element, it is rapidly heated, forming hot air. The fan speed and air volume can be adjusted through the control circuit, controlling the intensity and temperature of the hot air.

Meanwhile, the design of the hot air gun’s air outlet is also part of airflow control. The size and shape of the outlet affect the distribution and spray distance of the hot air. Users can adjust the direction and size of the outlet to meet different work requirements.

IV. Conclusion

The working principle of the hot air gun involves three key components: the heating element, temperature control system, and airflow control. The heating element provides the heat source for the hot air gun by converting electrical energy into thermal energy. The temperature control system ensures a stable temperature output during operation, and airflow control determines the intensity and direction of the hot air. These three components work together, making the hot air gun an efficient and versatile thermal tool widely used in various industrial, handicraft, and household applications.