SK-YJ000HT-KP 100020

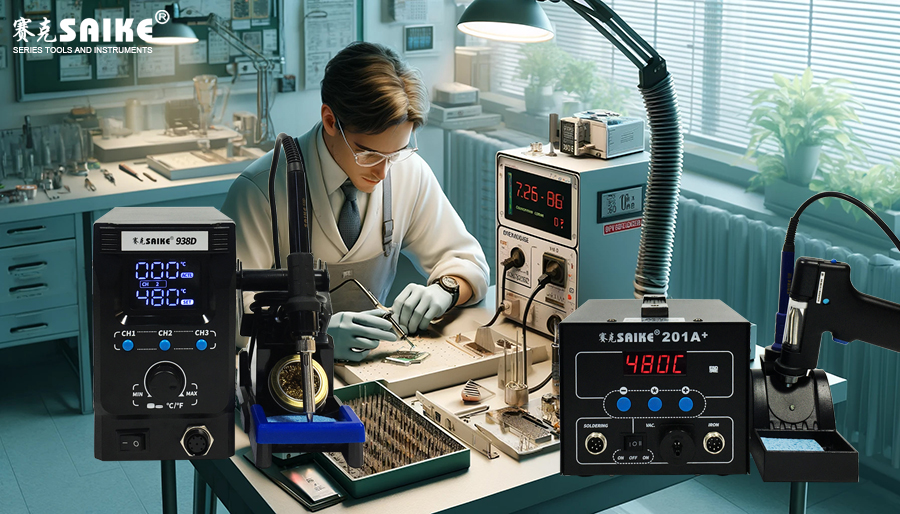

Proper setup and preheating of the soldering station are crucial for ensuring soldering quality and safety. The preheating process ensures that the soldering station reaches a suitable temperature for soldering, which helps improve soldering efficiency and extend equipment lifespan. This article will detail how to correctly set up the soldering station and perform preheating operations, highlighting the importance of this process.

I. Preparation Before Starting the Soldering Station

Before turning on the soldering station, several preparations should be made to ensure the safety and suitability of the equipment and operating environment.

1.Equipment Inspection

– Ensure that the soldering station and its accessories (such as soldering iron, soldering iron holder, solder sucker, etc.) are intact.

– Check the power cord and plug for damage, ensuring all connections are tight and there are no exposed wires.

2.Prepare the Work Area

– Clear the work surface, removing any items that may hinder soldering or pose a safety hazard.

– Verify adequate lighting and good ventilation conditions, ensuring the soldering area has proper exhaust facilities.

3.Personal Protective Equipment

– Wear appropriate protective gear based on the soldering task, such as protective glasses, heat-resistant gloves, and antistatic clothing.

II. Starting the Soldering Station

Once the above preparations are complete, you can safely start the soldering station following these steps.

1.Connecting the Power Supply

– Confirm that the soldering station switch is in the off position before connecting to the power supply.

– Connect the soldering station to a power outlet that meets its voltage and current requirements.

2.Turning on the Device

– Turn on the soldering station’s power switch. Most modern soldering stations have a power indicator light to confirm it’s on.

III. Preheating Process

Preheating is a crucial step before using the soldering station, ensuring it reaches a suitable operating temperature for soldering.

1.Setting the Desired Temperature

– Adjust the soldering station’s temperature based on the solder type and material characteristics. Generally, lead-free solder requires a higher temperature than traditional tin-lead solder.

– Use the soldering station’s temperature control device to set the appropriate temperature. Most soldering stations allow users to set precise temperatures.

2.Observing the Preheating Status

– Wait for the soldering station to reach the preset temperature. Most soldering stations have a temperature indication system that displays the current temperature in real-time.

– Preheating time depends on the soldering station model and power, usually within a few minutes.

3.Verifying Temperature Stability

– Use a dedicated soldering thermometer or infrared thermometer to check the actual temperature of the soldering iron tip, ensuring it matches the set value.

– Observe temperature stability to ensure there are no significant fluctuations during continuous use.

IV. Inspection After Preheating

Perform a final safety and performance check before starting to solder.

1.Checking the Soldering Iron Tip

– Ensure the soldering iron tip is clean, free of impurities, and undamaged.

– Use a damp sponge to gently clean the soldering iron tip if necessary, removing any oxides.

2.Actual Soldering Test

– Perform some test soldering on a discarded circuit board to check if the soldering effect meets the requirements.

V. Conclusion

The correct setup and preheating process form the foundation for using a soldering station, affecting soldering quality and equipment operation. By following these detailed steps, operators can improve soldering efficiency, extend equipment lifespan, and ensure soldering safety.