SK-YJ000XYY-KP 100020

Environmental protection regulations are becoming increasingly stringent globally, especially regarding pollution emissions from industrial production. Welding operations, as part of the industrial process, have received particular attention due to the potential hazards of harmful fumes generated by welding to the environment and human health. Smoking extraction systems, as crucial equipment for controlling and reducing welding fume emissions, are significantly influenced and constrained by environmental protection regulations in terms of their use and performance. This article explores the role and requirements of smoking extraction systems in meeting environmental protection regulations.

I. Overview of Environmental Protection Regulations

1.Emission Standards

– Many countries and regions have established strict air quality standards, specifying the maximum allowable concentrations of harmful substances emitted into the atmosphere, such as the Clean Air Act in the United States and relevant directives in the European Union.

2.Workplace Health and Safety Standards

– Welding fumes are considered a risk factor for occupational health. Relevant regulations require employers to take measures to reduce pollutant concentrations in the workplace and ensure workers’ health, as stipulated by agencies like the Occupational Safety and Health Administration (OSHA) in the United States.

3.Environmental Certifications and Labels

– Certain environmental certifications, such as Energy Star or green technology labels, encourage or require the use of efficient and low-polluting equipment.

II. Regulatory Adaptability of Smoking Extraction Systems

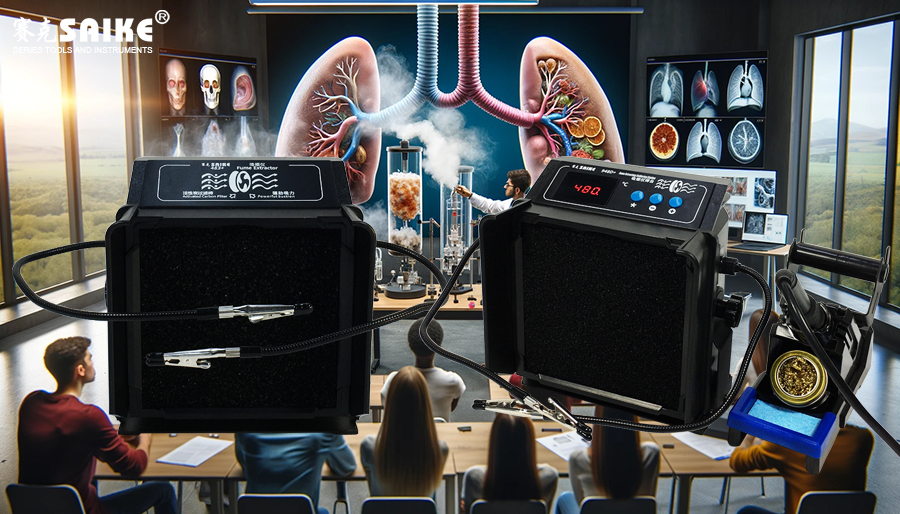

1.High-Efficiency Filtration Technology

– Modern smoking extraction systems are often equipped with HEPA filters and activated carbon layers. These technologies help businesses meet strict air quality standards and reduce environmental impact.

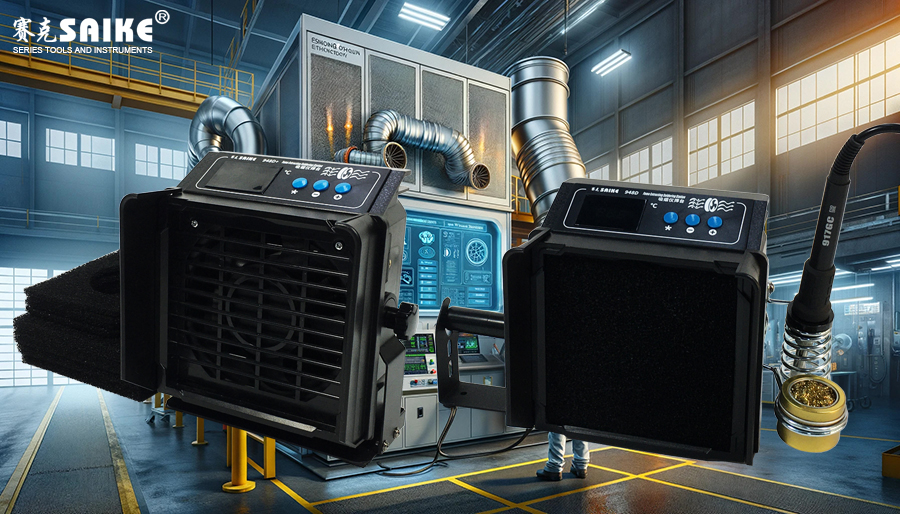

2.Energy and Material Efficiency

– Regulations may require smoking extraction systems to consider energy efficiency in their design and operation, reducing energy consumption and using sustainable or recyclable materials.

3.Emission Monitoring and Reporting

– To comply with regulatory requirements, smoking extraction systems may need to integrate monitoring equipment to real-time monitor filtration efficiency and emission levels, and regularly report to environmental agencies.

III. Impact of Environmental Regulations on Businesses

1.Compliance Costs

– Businesses need to invest in compliant smoking extraction systems and other environmental protection facilities, which may increase initial investment and operational costs.

2.Training and Maintenance

– Equipment that meets environmental regulations may require special operation and maintenance knowledge. Companies need to train employees to ensure the correct use and maintenance of the equipment.

3.Market Advantage

– Using high-standard environmental protection equipment can be part of corporate social responsibility, enhancing the company’s image and enhancing market competitiveness.

IV. Conclusion

Smoking extraction systems, as crucial tools for reducing industrial welding fume emissions, play a key role in complying with and adapting to environmental regulations. With increasing environmental awareness and stricter regulations, the technology and application of smoking extraction systems will continue to progress to meet higher environmental and health standards. When selecting and using smoking extraction systems, companies should consider not only their technical performance but also how they can help achieve regulatory requirements, thereby playing a role in protecting the environment and promoting sustainable development.