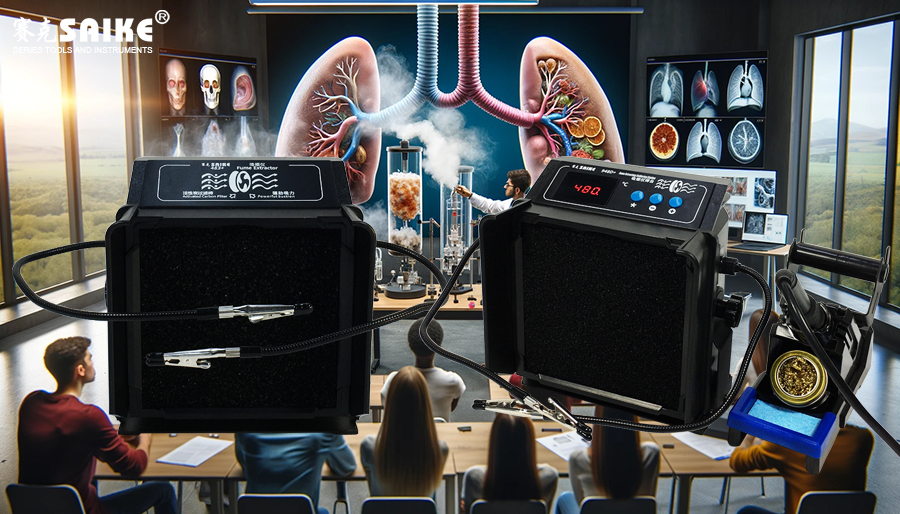

SK-YJ000XYY-KP 100010

To ensure the safe and effective use of smoking absorbers, it is crucial to adhere to a series of operating procedures. Here are some basic safe operating procedures for using smoking absorbers:

I. Preparation

1.Read the User Manual

– Before using the smoking absorber, be sure to read the user manual provided by the manufacturer in detail to understand the function, operating steps, and safety warnings of the equipment.

2.Check Equipment Status

– Check the equipment for any damage or abnormalities before each use. Confirm that all electrical connections are secure and show no signs of loosening or wear.

3.Confirm the Working Environment

– Ensure that the working environment is well-ventilated, and the smoking absorber should be placed away from flammable substances and water sources.

II. Operating Process

1.Correct Installation and Configuration

– Install and configure the smoking absorber according to the manual, ensuring that all components are correctly installed, especially the filtration system and exhaust facilities.

2.Avoid Overload

– Do not exceed the design capacity of the equipment and avoid handling excessive amounts of smoke simultaneously, which may cause the equipment to overheat or decrease efficiency.

3.Use Appropriate Settings

– Adjust the air speed and filtration settings of the smoking absorber according to different types of operations and smoke volumes to ensure maximum smoke capture efficiency.

III. Maintenance and Inspection

1.Regular Maintenance

– Perform regular maintenance according to the manufacturer’s recommendations, including cleaning the equipment, checking, and replacing filters.

2.Check the Electrical System

– Regularly inspect wires and electrical connections to avoid short circuits or fires caused by aging or damage.

3.Record Maintenance and Operation Logs

– Record the time of each maintenance and component replacement, as well as equipment usage, which helps to detect potential problems in a timely manner and perform preventive maintenance.

IV. Accident Response

1.Develop an Emergency Response Plan

– Develop an emergency response plan for possible equipment failures or accidents, ensuring that all operators understand how to shut down the equipment and take safety measures in an emergency.

2.Equipment Failure Shutdown

– If the smoking absorber exhibits abnormal noise, overheating, or ineffective smoke processing, it should be immediately shut down for inspection, and technical support should be contacted if necessary.

V. Training and Guidance

1.Operator Training

– Ensure that all operators have received training on the operation and safety of smoking absorbers, understanding how to safely use and maintain the equipment.

2.Continuous Education

– As equipment technology updates and the work environment changes, regularly update training materials and courses to ensure that operators’ knowledge is up-to-date.

VI. Conclusion

Adhering to these safe operating procedures can significantly improve the safety and efficiency of using smoking absorbers. Regular maintenance and correct operation can not only extend the equipment’s lifespan but also protect the health and safety of operators.