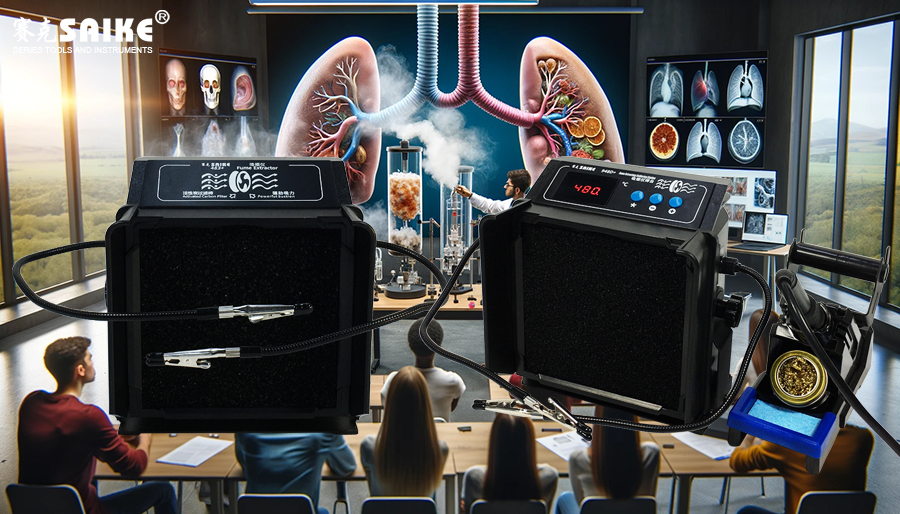

SK-YJ000XYY-KP 100009

Ensuring the accuracy and efficiency of smoking absorbers is a crucial step in maintaining a safe work environment. Proper testing and calibration can help monitor the performance of the equipment, detect problems in a timely manner, and make adjustments. Here are some standard methods for testing and calibration of smoking absorbers:

I. Testing Methods

1.Performance Testing

– Airflow Testing: Use an anemometer or similar instrument to measure the airspeed and airflow of the fan to ensure it meets the manufacturer’s specifications.

– Filtration Efficiency Testing: Measure the number of particles entering and leaving the filtration system using a particle counter to calculate whether the filtration efficiency meets the HEPA standard (i.e., removing 99.97% of 0.3-micron particles).

2.Smoke Capture Effectiveness Testing

– Generate standardized smoke or aerosol during equipment operation and use a particle analyzer or smoke test tube to detect the capture and filtration effectiveness of the smoking absorber.

3.Noise Level Testing

– Use a decibel meter to test the noise level generated during the operation of the smoking absorber to confirm whether it meets environmental safety standards.

II. Calibration Methods

1.Flow Calibration

– Use a standard flowmeter to calibrate the smoking absorber according to the parameters provided by the manufacturer to ensure that the fan output meets the specifications.

2.Sensor Calibration

– If the smoking absorber is equipped with detection sensors (such as particulate matter or chemical gas sensors), regularly perform sensor calibration to ensure the accuracy of the readings. The calibration process may require the use of standard gases or calibration kits.

3.Filter Inspection

– Regularly inspect and replace filters, and retest the filtration efficiency after replacing new filters to ensure their performance meets the requirements.

III. Maintenance and Adjustment

1.Regular Cleaning

– Regularly clean the interior and exterior of the smoking absorber, especially the fan and filtration system, to prevent dust and particles from clogging and affecting performance.

2.Software Updates

– If the smoking absorber includes a digital control system, ensure that its software remains updated to take advantage of the latest features and performance improvements.

3.Preventive Maintenance

– Regularly perform preventive maintenance checks, including inspecting electrical connections, wear and tear of mechanical components, and possible air leaks.

IV. Conclusion

Through these testing and calibration methods, the performance and safety of smoking absorbers can be effectively ensured. To ensure the long-term operation of the equipment and the health of the staff, it is recommended to follow the manufacturer’s maintenance guidelines and conduct regular professional inspections and calibrations. This can not only extend the service life of the equipment but also ensure its efficiency in removing harmful smoke and gases.