SK-YJ000XYY-KP 100001

I. Definition and Role of Fume Extractors

1.Definition

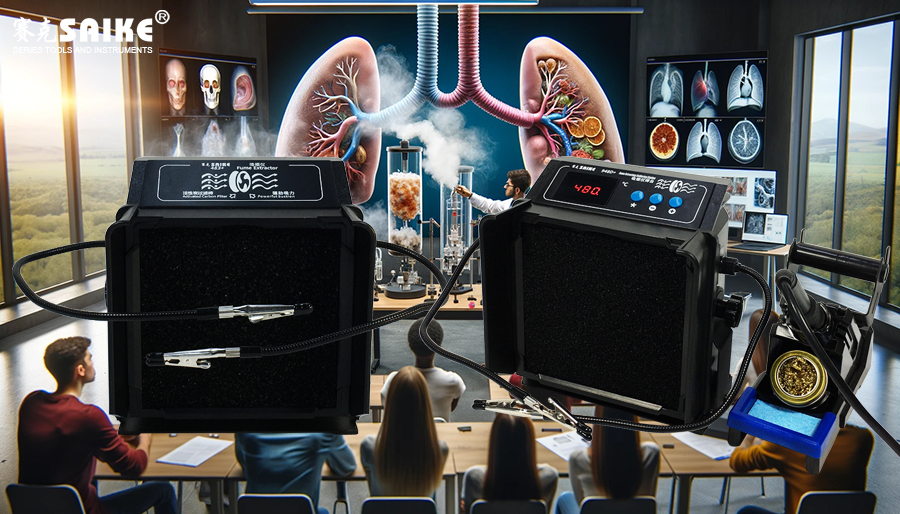

– A fume extractor, also known as a smoke extractor or fume absorber, is a device designed to absorb, filter, and eliminate harmful fumes and gases generated during welding processes. It primarily consists of a fan, a filtering system, and an exhaust unit.

2.Role

– Health Protection: Welding fumes contain various harmful substances such as heavy metals like lead, cadmium, chromium, and multiple organic compounds. Fume extractors, through their efficient filtering systems, minimize the inhalation of these harmful substances, safeguarding the respiratory health of operators.

– Environmental Protection: By filtering and purifying fumes, they reduce pollution in laboratories and industrial environments, aligning with environmental standards.

– Efficiency Improvement: A cleaner work environment leads to reduced maintenance frequency and malfunction rates, thereby enhancing production efficiency.

II. Applications of Fume Extractors in Laboratories

1.Chemistry Experiments: During chemical syntheses and experiments, fume extractors effectively suck away toxic gases and fumes produced during reactions, protecting the health of laboratory personnel and maintaining a clean laboratory environment.

2.Biotechnology Experiments: In biological experiments involving cell cultures and genetic engineering, these extractors prevent the inhalation of harmful substances and minimize cross-contamination.

3.Materials Science: In the research and development of new materials, such as synthetic polymers, fumes and vapors generated can be effectively controlled and disposed of using fume extractors.

III. Applications of Fume Extractors in Industrial Settings

1.Electronics Manufacturing: During processes like electronic welding and circuit board manufacturing, fume extractors are used to suck away welding fumes, which often contain flux and metal oxides harmful to operators’ health.

2.Machine Manufacturing: In metal processing and welding, these extractors efficiently remove welding fumes and dust, protecting the respiratory system of workers and reducing wear and tear on machinery.

3.Automobile Manufacturing: In welding and painting operations in automobile workshops, fume extractors significantly improve the working environment, preventing long-term accumulation of harmful substances and the development of occupational diseases.

IV. Conclusion

As an effective environmental and health protection device, fume extractors are increasingly used in laboratories and industrial settings. They not only enhance work efficiency but also ensure a safe and clean working environment, making them an indispensable equipment in modern industrial production and scientific research. With technological advancements, the functionality and efficiency of fume extractors continue to improve, providing strong support for achieving more environmentally friendly and healthy working conditions.