SK-YJ000XYY-KP 100016

During welding operations, the melting of metals and heating of soldering materials often generate a large amount of harmful smoke and gases. These fumes pose a serious threat to the health of operators. Therefore, the use of smoking apparatus has become an indispensable safety measure in special welding environments. This article will explore in detail the application of smoking apparatus in special welding environments, including its working principle, application scenarios, and how to properly select and use smoking apparatus to ensure the safety and efficiency of welding operations.

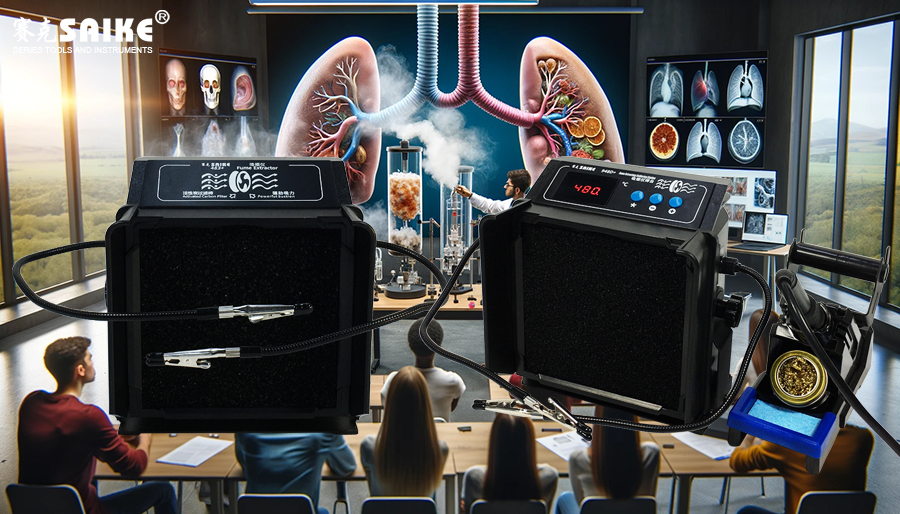

I. Working Principle and Types of Smoking Apparatus

1.Working Principle:

– The smoking apparatus mainly sucks in air through a powerful fan and captures and filters harmful smoke and particulate matter in the air using an efficient filtration system (such as a HEPA filter).

– An efficient carbon filter layer can further adsorb harmful gases and odors, thereby purifying the environment.

2.Common Types:

– Portable Smoking Apparatus: Suitable for small-scale or highly mobile welding operations, easy to transport.

– Fixed Smoking Apparatus: Suitable for fixed workstations, with stronger suction power and a large-capacity filtration system, suitable for continuous welding operations over a long period of time.

– Integrated Smoking Apparatus: Directly integrated into welding equipment, such as welding robots, which can instantly absorb and filter smoke at the source.

II. Application Scenarios of Smoking Apparatus in Special Welding Environments

1.Electronic Assembly and Repair:

– When welding or repairing circuit boards, the smoking apparatus can effectively remove lead and other toxic metal vapors caused by soldering.

2.Welding in Confined Spaces:

– When performing welding operations in confined spaces such as ships or submarines, the smoking apparatus can significantly reduce the accumulation of harmful smoke and protect workers from toxic gases.

3.Automated Welding Operations:

– In production lines using welding robots and automated welding equipment, integrated smoking apparatus can be directly installed near the equipment to effectively control the direct emission of smoke and keep the production environment clean and safe.

III. Suggestions for Selecting and Using Smoking Apparatus

1.Performance Selection:

– Select the appropriate smoking apparatus model and specifications based on the environment and frequency of welding operations to ensure that its filtration capacity meets work requirements.

– Confirm whether the noise level of the smoking apparatus meets the quiet needs of the work environment.

2.Regular Maintenance and Filter Replacement:

– Regularly inspect and replace the filter and carbon filter layer to ensure efficient operation of the smoking apparatus.

– Clean the fan and body to prevent dust and dirt accumulation from affecting performance.

3.Operator Training:

– Provide training on the use and maintenance of smoking apparatus to operators to ensure that each employee can operate the equipment correctly and effectively utilize its functions.

IV. Conclusion

Smoking apparatus plays a crucial role in special welding environments, not only protecting the health of workers but also helping to maintain a clean and safe production environment. By making reasonable choices and scientifically using smoking apparatus, the safety and efficiency of welding operations can be significantly improved. In the purchase and use process, various environmental factors and operational requirements should be fully considered to achieve the best use effect.