SK-YJ000XYY-KP 100018

With the advancement of technology, the importance of smoking apparatus in welding operations has become increasingly prominent, especially in improving environmental safety and operational efficiency. The application of innovative technologies has made modern smoking apparatus more efficient, intelligent, and environmentally friendly than in the past. In this article, we will explore the application of several innovative technologies in smoking apparatus and analyze how these technologies are changing the safety and efficiency of welding operations.

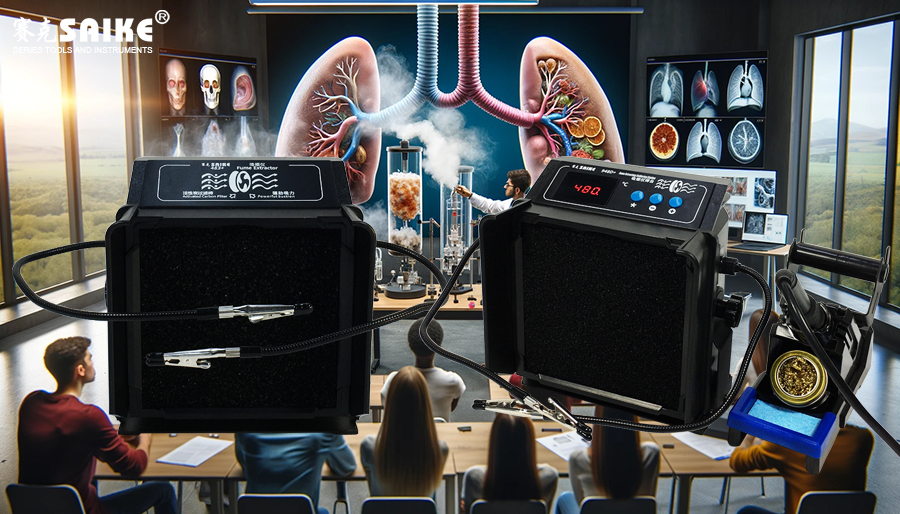

I. High-Efficiency Filtering Technology

1.HEPA High-Efficiency Particulate Air Filtering

– HEPA filtering technology can capture at least 99.97% of particles with a diameter of 0.3 microns, greatly improving the ability to filter smoke and particulates.

– In welding operations, this means that almost all harmful smoke and particulates can be effectively filtered out, greatly improving the air quality of the work environment.

2.Activated Carbon Layer

– The activated carbon layer is used to adsorb harmful gases and odors in the smoke, which is particularly important for handling various chemicals generated during welding.

– This technology not only improves air quality but also helps reduce health risks to operators.

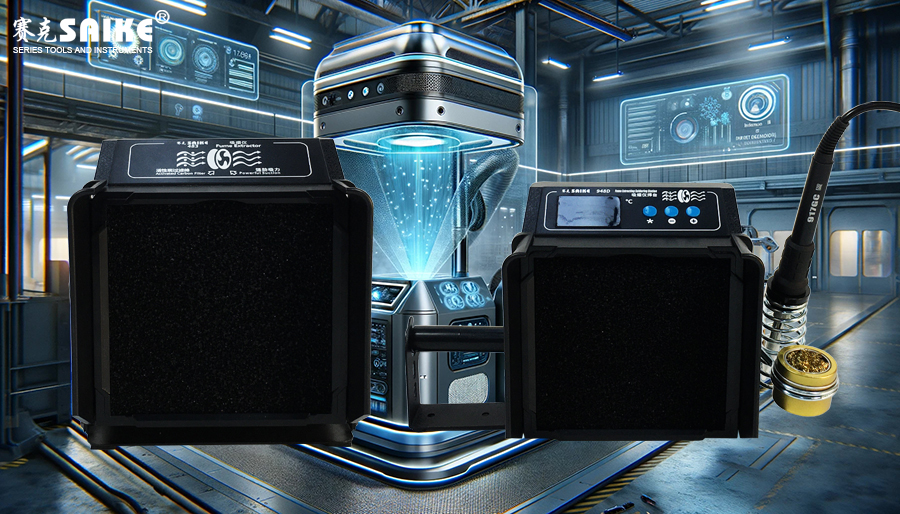

II. Intelligent Control System

1.Automatic Fan Speed Adjustment

– Modern smoking apparatus can automatically adjust the fan speed based on the density of smoke, optimizing energy use and extending the equipment’s lifespan.

– This intelligent adjustment ensures efficient smoke removal under different welding conditions.

2.Remote Monitoring and Control

– Through Wi-Fi or Bluetooth technology, the smoking apparatus can be connected to smart devices, allowing operators to remotely monitor and control the equipment.

– This provides greater flexibility, making it easier for operators to manage air quality across multiple workstations.

III. Sustainable Technologies

1.Energy Efficiency Optimization

– By adopting efficient motors and fans, the energy efficiency of modern smoking apparatus has been significantly improved.

– This not only reduces energy consumption but also helps reduce operating costs.

2.Recycling of Filtering Materials

– New smoking apparatus designs include recyclable filtering materials that can be cleaned and regenerated, reducing the amount of filtering material that needs to be regularly replaced.

– This design reduces waste generation and aligns with the sustainable development concept of environmental protection.

IV. Conclusion

Through the introduction of innovative technologies, smoking apparatus have played a key role in improving environmental safety and operational efficiency in welding operations. Efficient filtering systems, intelligent control technology, and sustainable design concepts not only enhance the performance of smoking apparatus but also provide a safer and more convenient work environment for operators. The integration of these technologies makes smoking apparatus an indispensable part of welding work, greatly promoting welding safety and environmental protection progress.