SK-YJ000ZLWYDY-KP 100031

I. Introduction

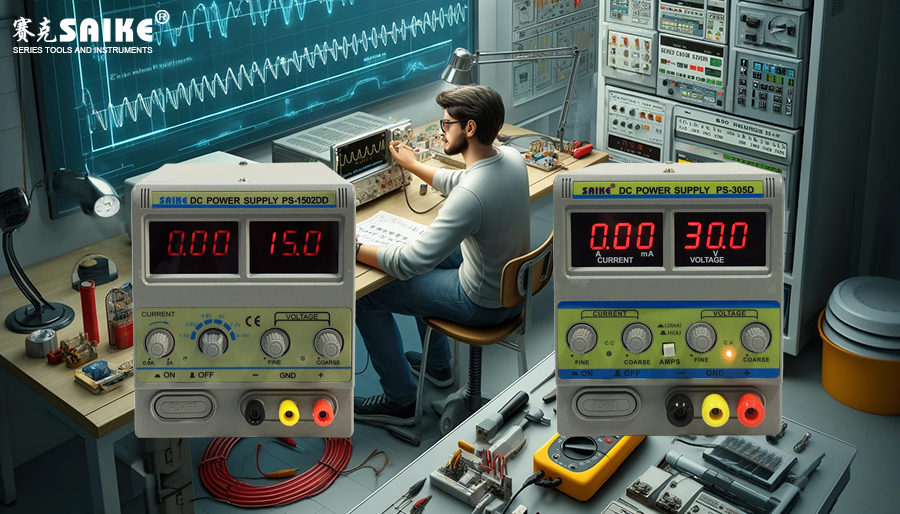

Preliminary testing and debugging of DC stabilized power supplies are crucial steps to ensure that their performance meets design requirements. The correct testing methods not only help identify and address potential issues but also verify the stability and efficiency of the power supply. The following content will introduce how to conduct preliminary testing and debugging of DC stabilized power supplies.

II. Preparation of Testing Equipment

1.Necessary Testing Equipment

– Digital Multimeter: Used to measure voltage, current, and resistance.

– Adjustable Load: Used to simulate the power load under actual working conditions.

– Oscilloscope: Used to observe voltage stability and ripple.

– Thermal Imager or Thermometer: Used to detect the operating temperature of components.

2.Work Environment Preparation

– Ensure that the workbench is clean, tidy, and well-lit.

– Prepare electrostatic protection facilities, such as anti-static bracelets and mats.

III. Preliminary Electrical Testing

1.Visual Inspection

– Before powering on, carefully inspect the soldering points on the circuit board for damage and confirm that there are no obvious soldering errors such as cold solder joints, short circuits, or misalignments.

2.Connectivity Test

– Use the buzzer function of the digital multimeter to check whether the input and output paths of the power supply are unobstructed, confirming no breaks or short circuits.

3.Static Test

– Connect the power input and use a digital multimeter to measure the output voltage, confirming whether it reaches the designed value under no-load conditions.

IV. Load Testing and Adjustment

1.Gradually Increasing Load

– Initially set a lower load and gradually increase it to the maximum designed load, observing voltage changes.

– Record the output voltage and current under different loads to verify compliance with specifications.

2.Ripple and Noise Measurement

– Use an oscilloscope to measure the ripple and noise of the output voltage.

– Ensure that ripple and noise levels are within an acceptable range and meet design specifications.

V. Efficiency and Thermal Testing

1.Efficiency Test

– Calculate input and output power under different load conditions to derive efficiency.

– Compare with design expectations to check whether efficiency meets standards.

2.Thermal Performance Test

– After running the power supply under full load for a period, use a thermal imager or touch method (carefully to avoid burns) to check the temperature of key components.

– Confirm that the operating temperature of all components is within a safe range.

VI. Troubleshooting and Debugging

1.Problem Identification

– If abnormal output voltage or excessively high ripple is detected during testing, check whether related components such as capacitors, inductors, or voltage regulators have issues.

2.Adjustment and Optimization

– Adjust the feedback network, filtering capacitors, or other related circuit settings based on test results to optimize performance.

VII. Conclusion

Conducting preliminary testing and debugging of DC stabilized power supplies is an essential step to ensure their stability and reliability in practical applications. By comprehensively utilizing various testing equipment and methods, the performance of the power supply can be effectively evaluated, and problems can be promptly identified and addressed. Keeping systematic testing records and analyzing results hold significant value for future design improvements and trouble prevention.