SK-YJ000RFCHT-KP 100015

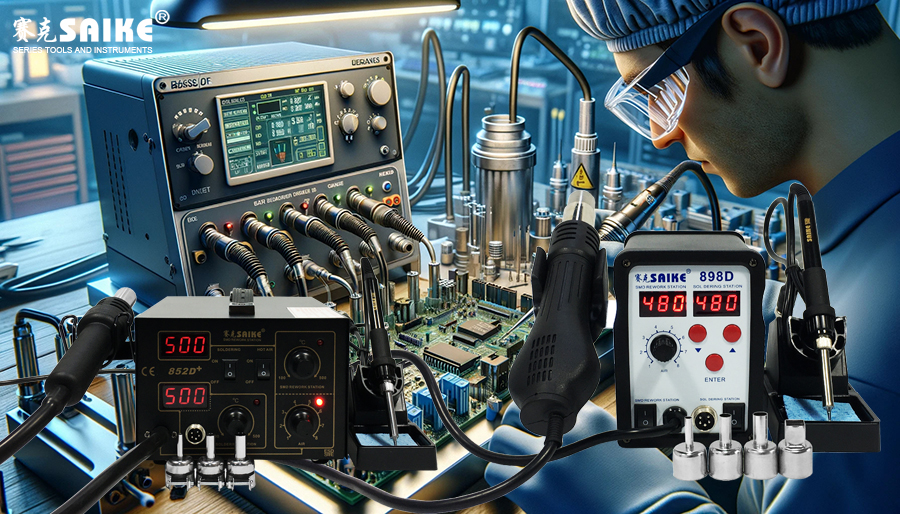

The hot air rework station is an indispensable tool in the electronic repair and manufacturing industries, enabling efficient soldering and desoldering through precise control of hot air. Mastering the operational skills of this equipment, whether basic or advanced, can significantly improve work efficiency and quality. This article will detail the basic and advanced operational skills of using a hot air rework station.

I. Basic Operational Skills:

1.Proper Temperature and Airflow Settings:

– Before starting any operation, adjust the appropriate temperature and airflow speed based on the type of solder and the characteristics of the electronic components. The temperature should not be too high to avoid damaging the components, and the airflow speed should be sufficient for uniform heating without blowing away the solder.

2.Using the Right Nozzle:

– Select the nozzle based on the target operation. Smaller nozzles are suitable for precision components, while larger nozzles are ideal for large-area heating. Ensure the nozzle matches the size of the desoldering area to optimize thermal efficiency.

3.Continuous Dynamic Heating:

– When using the hot air rework station, avoid pointing the hot air at one spot for too long. Slowly move within a small range to ensure uniform heat distribution and prevent local overheating.

4.Maintain Proper Distance:

– The recommended height of the nozzle from the circuit board is usually between 2 and 5 centimeters. Too close a distance can cause component overheating, while too far reduces thermal efficiency.

5.Timely Cooling Process:

– After soldering or desoldering, allow the hot air rework station to cool naturally or continue blowing with lower temperature air for a few seconds to help solidify the solder joints.

II. Advanced Operational Skills:

1.Multi-point Heating Technique:

– For large or complex components, use alternating heating, i.e., heating multiple solder joints alternately. This distributes heat more evenly, preventing damage to the solder pad due to overheating at a single point.

2.Fine Control of Solder Flow:

– Utilize the directionality of the hot air to control the flow of solder. For example, during desoldering, slightly tilt the nozzle to guide the solder in a direction that won’t affect other components.

3.Combined Use of Other Tools:

– Combine the use of a solder sucker or solder wick during desoldering operations. Soften the solder with hot air first, then quickly remove the melted solder using the suction tool for a cleaner and more thorough disassembly.

4.Temperature Level Application:

– For boards that require simultaneous desoldering of multiple components with different heat tolerances, start by setting a higher temperature to quickly remove high-temperature-resistant components, then lower the temperature for delicate handling of sensitive components.

5.Using Temperature Profiles:

– Advanced hot air rework stations often feature programmable temperature profiles. By setting temperature profiles, operators can precisely control the heating and cooling processes, adapting to different operational requirements and material properties.

III. Conclusion

In conclusion, effective operation of a hot air rework station, whether it’s basic or advanced skills, requires a deep understanding of the equipment’s performance and rich practical experience. By continuously adjusting and optimizing settings through practical operations, combined with correct operational skills, the quality and efficiency of soldering and desoldering can be significantly improved. Continuously learning and adapting to new techniques and methods will enable operators to better master the use of hot air rework stations to tackle various complex electronic manufacturing and repair tasks.