SK-YJ000XYY-KP 100023

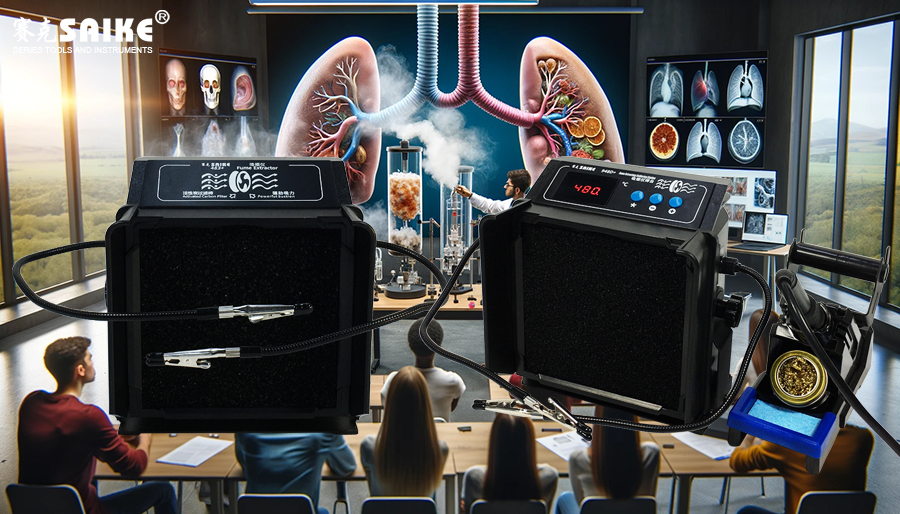

In welding operations, the correct use of smoking apparatus is crucial to ensure a safe and healthy working environment. To improve operators’ proficiency and equipment efficiency, practical operation drills and skill verification are essential. This article will introduce how to effectively conduct operation drills for smoking apparatus, as well as the methods and standards for skill verification.

I. Preparation for Operation Drills

Goal Setting

– Understanding Equipment Functions: Ensure that all operators understand the basic functions and operating interface of the smoking apparatus.

– Familiarity with Safety Operating Procedures: Emphasize safety guidelines for using the smoking apparatus, including startup, shutdown, cleaning, and maintenance.

Equipment and Material Preparation

– Smoking Apparatus and Accessories: Prepare the actual smoking apparatus to be used, along with all necessary accessories and tools.

– Operation Manual: Provide the operation manual or user guide for the smoking apparatus, ensuring detailed reference materials are available.

Safety Measures

– Personal Protective Equipment: Ensure that all participants are equipped with appropriate personal protective equipment (PPE), such as safety goggles and protective gloves.

– Emergency Response Preparation: Clarify the location and use of the emergency stop button to ensure a rapid response in emergency situations.

II. Practical Operation Drills

Drill Process

1.Equipment Inspection:

– Ensure that the smoking apparatus is in good working condition.

– Check that all connections and power settings are safe and reliable.

2.Basic Operations:

– Follow the operation manual to start up, set the air speed, and choose the operating mode.

– Demonstrate how to adjust the suction nozzle position to maximize smoke capture efficiency.

3.Maintenance Drills:

– Demonstrate and practice the process of replacing filters and cleaning the interior of the smoking apparatus.

– Explain and demonstrate the steps for regular maintenance, including checking the motor and fan.

4.Troubleshooting:

– Conduct drills for common fault situations and corresponding solutions.

– Emphasize how to identify signs of equipment failure and report them promptly.

Feedback and Discussion

– After the drill, collect feedback from all participants and discuss possible improvements.

– Reinforce the importance of correct operation and answer questions about the process.

III. Skill Verification

Verification Standards

– Operational Proficiency: Verify that operators can skillfully start up, operate, and shut down the smoking apparatus.

– Maintenance Capability: Assess whether operators can correctly perform routine maintenance and filter replacements.

– Fault Response: Test operators’ reaction speed and handling ability when facing equipment failures.

Verification Methods

– Practical Operation Test: Test operators’ skills by simulating daily work operations.

– Written Test: Conduct a written test to assess operators’ knowledge and understanding of smoking apparatus operations.

– Regular Reviews: Set regular review cycles to ensure that operators’ skills remain at a high standard.

IV. Summary

Through systematic operation drills and skill verification, not only can operators improve their efficiency and safety in using the smoking apparatus, but they can also enhance their ability to maintain equipment and handle faults. These activities help ensure a safe welding environment, protect employee health, and improve overall production efficiency.