SK-YJ000XYY-KP 100017

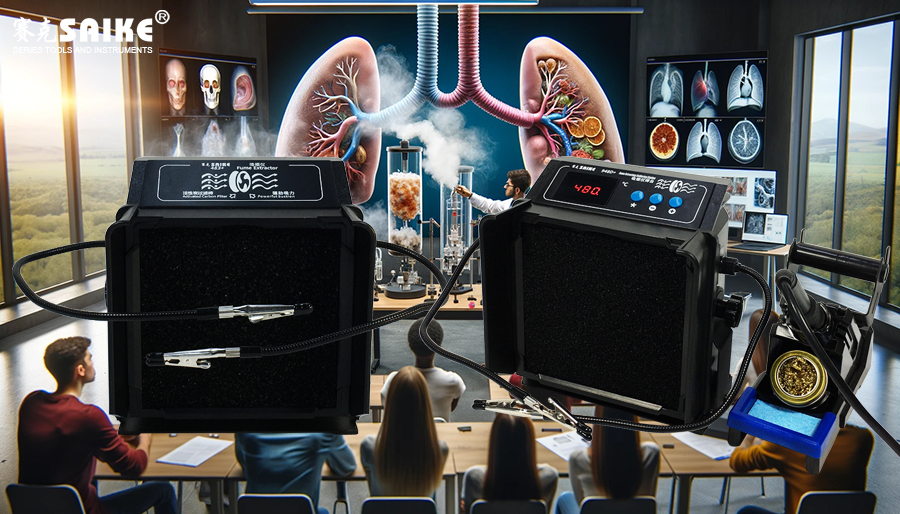

In welding operations, the smoking apparatus is a critical device used to control and reduce the release of harmful fumes. However, to achieve higher operational efficiency and safety, the smoking apparatus often needs to be used in conjunction with other welding auxiliary tools. This article will explore how to effectively combine the smoking apparatus with other welding auxiliary tools to improve welding quality and workplace safety.

I. Common Welding Auxiliary Tools

1.Welding Table:

– Provides a stable working platform to ensure precise and safe welding operations.

– Usually equipped with a surface made of high-temperature resistant and fireproof materials.

2.Welding Clamp:

– Used to fix welding materials, ensuring stable material positioning during the welding process.

– Helps improve the consistency and quality of welded joints.

3.Protective Screen:

– Isolates the welding area, preventing welding sparks and fumes from spreading to the surrounding environment.

– Can reduce safety risks to operators and bystanders.

II. Combined Application of Smoking Apparatus and Other Tools

1.Combination with Welding Table:

– Adjust the suction port position of the smoking apparatus near the welding point to ensure that the fumes are quickly sucked away when generated.

– Consider the integration of the welding table and smoking apparatus during design to make smoke control more efficient.

2.Collaboration with Welding Clamp:

– Ensure that the configuration of the smoking apparatus can adapt to different sizes and shapes of weldments, matching the adjustment range of the welding clamp.

– Use a movable smoking apparatus or a model with a flexible arm to adapt to various weldments fixed by the welding clamp.

3.Joint Use with Protective Screen:

– Incorporate specific vents into the design of the protective screen, allowing the smoking apparatus to more effectively suck away the fumes in the enclosed area.

– Consider the air flow design between the protective screen and the smoking apparatus to ensure that fumes do not linger in the work area.

III. Optimization Suggestions

1.System Integration Design:

– When purchasing new welding equipment, consider the integrated design of the smoking apparatus with welding tables, welding clamps, protective screens, and other equipment to optimize work processes and space utilization.

2.Regular Inspection and Maintenance:

– Regularly inspect the interface between the smoking apparatus and other welding tools to ensure efficiency and safety when all devices are working together.

– Maintain and repair the filtration system of the smoking apparatus to maintain optimal smoking effect.

3.Operational Training:

– Provide comprehensive training to welding operators on the use of smoking apparatus and other auxiliary tools to ensure that each operator is proficient in using the equipment.

IV. Conclusion

In special welding environments, the effective combination of smoking apparatus and other welding auxiliary tools can not only improve the safety and efficiency of welding operations but also enhance the working environment and reduce health risks. Through careful design and maintenance, the synergistic effect of these tools will greatly improve welding quality and the overall performance of the work environment.