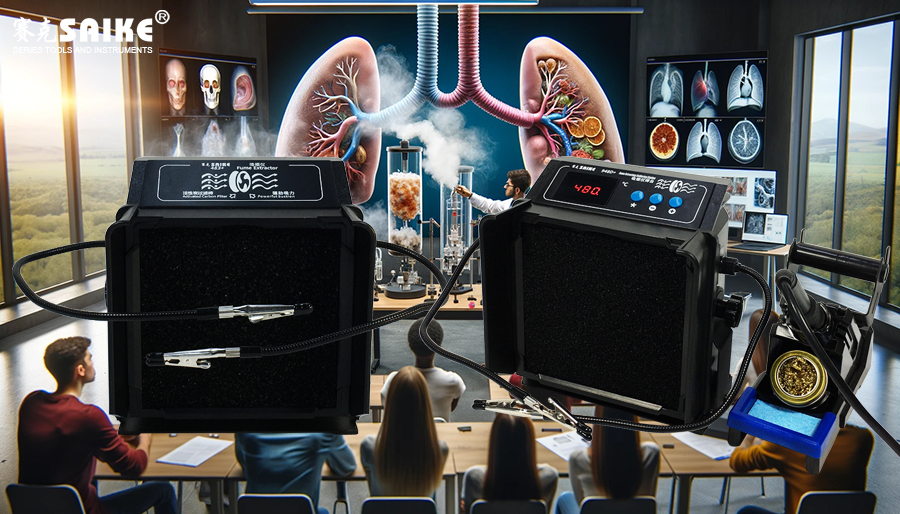

SK-YJ000XYY-KP 100013

Daily maintenance and cleaning are crucial to ensuring the continuous and efficient operation of the smoking absorber. Here are some basic maintenance and cleaning steps that can help extend the lifespan of the smoking absorber and maintain its optimal performance:

I. Daily Maintenance

1.Filter Inspection

– Regular Inspection: Regularly check the degree of filter clogging based on the frequency of use. If a large amount of particulate matter is found to accumulate on the filter surface, it may affect the suction and filtration efficiency of the smoking absorber.

– Filter Replacement: Follow the manufacturer’s recommended replacement cycle. For high-frequency use environments, more frequent replacements may be required.

2.Cleaning of Fan and Internal Mechanics

– Fan: Dust accumulation on the fan can reduce efficiency and increase operating noise. Use a soft brush or compressed air to remove dust from the fan.

– Internal Mechanical Components: Regularly check internal mechanical components for signs of wear or damage, and ensure that all moving parts are well-lubricated.

3.Electrical Component Inspection

– Cables and Plugs: Check the power cord and plug for signs of damage or wear. Any electrical faults should be addressed immediately to prevent safety accidents.

II. Cleaning Operations

1.Cleaning the Exterior

– Gently wipe the exterior of the smoking absorber with a wet cloth. Avoid using corrosive cleaners that may damage the surface.

2.Cleaning the Intake and Exhaust Ports

– Intake Port: Ensure that the intake port is clean and unobstructed, regularly clean it using a soft brush or compressed air.

– Exhaust Port: Also, ensure that the exhaust port is clear and free of any blockages, regularly removing any impurities that may clog it.

3.Preventing Liquid Intrusion

– Avoid liquid entering the interior of the smoking absorber during the cleaning process. Liquids can damage circuit boards and other sensitive components.

III. Recording Maintenance Activities

– Keep a maintenance log, recording the date of each inspection, cleaning, and component replacement, as well as any issues found. This helps track the overall health of the equipment and predict potential repairs that may be needed.

IV. Vocational Training

– Ensure that operators receive proper training on how to perform daily maintenance and cleaning. This not only helps maintain the optimal operating state of the equipment but also prevents equipment failures caused by misoperation.

By following these maintenance and cleaning steps, the operational efficiency and reliability of the smoking absorber can be significantly improved, reducing failure rates and ensuring continuous safety for the operating environment.